Phase Transition Analyzer®

Accurately measure the phase points of a mixed biopolymer and map the extrusion process

Within an extruder, it’s necessary for the product to be near its melting point for optimal blending and cooking, and above its melting point to exit the die. However, changes in recipes and raw material sources can create process challenges for an extruder operator, especially to maintain output consistency.

To maximize extrusion cooking performance, it’s vital to predict how the product (a mixed biopolymer) will change at different temperatures and moisture levels under pressure.

The Phase Transition Analyzer®, designed and patented by Wenger, provides data to accurately map the entire extrusion cooking process - from preconditioning, to extrusion, to drying/cooling.

This data allows an extruder operator to improve management of moisture and energy inputs during operation.

Key Features

-

Temperature range: 5 – 200°C

-

Heating and cooling rates up to 25°C/min

-

Pressure measurement and control up to 210 bar

-

Software package to measure and record temperature, pressure, and sample movement

-

Real time graphical display of data during testing

-

Data analysis software to determine Tg and Tm

-

CE compliance

-

Weight: 45 kg

How it Works

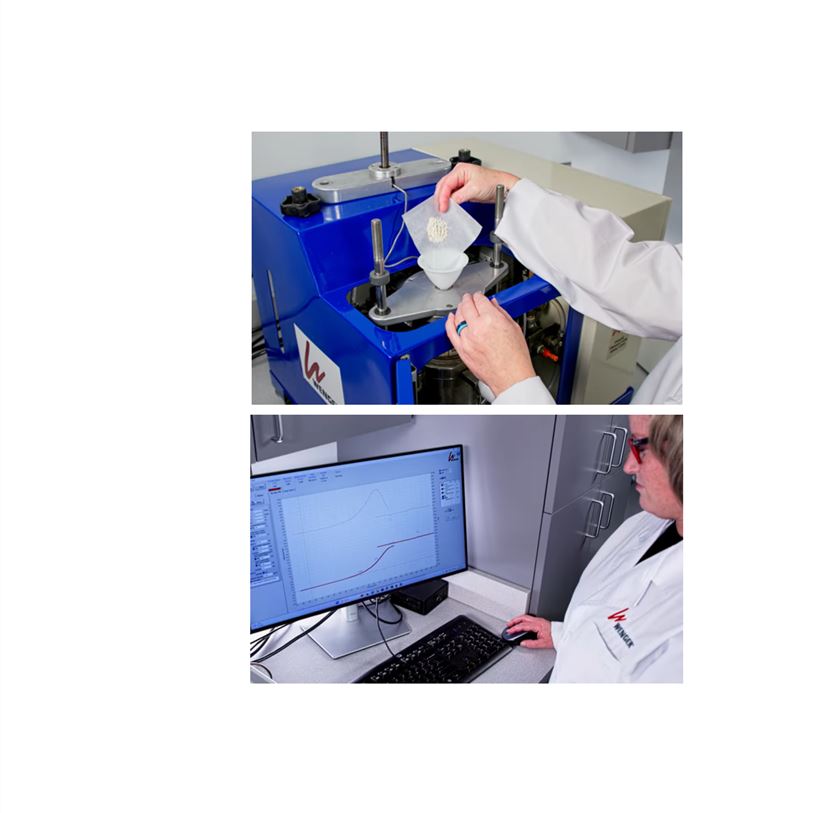

The Phase Transition Analyzer is a closed-chamber capillary rheometer, which uses a combination of pressure, temperature, time and moisture to measure the Tg and Tm of a biopolymer. It consists of two sealed chambers, separated by an interchangeable capillary die, that prevents sample moisture loss so testing can be at temperatures far exceeding 100°C. The sample chamber is of fixed volume, and a constant pressure is maintained on the sample throughout the test. The sample movement, which is tracked and recorded during testing, is used to determine the sample’s controlling Tg and Tm.

The Phase Transition Analyzer provides knowledge about the Tg and Tm of a biopolymer that can be directly applied to the extrusion cooking process. When a sample’s Tg and Tm is combined with a mass and energy audit of an extrusion system, it enables an extrusion technologist to accurately map the process – a valuable aid to troubleshooting and better characterization of the extrusion operation. The Phase Transition Analyzer data also has been correlated to important properties of both raw materials and extruded products.

NOTE: A chilled coolant supply is required to achieve temperatures below room temperature.

Chiller specifications for best performance with the PTA:

- Temperature range: -10 to 30°C

- Cooling flow requirements: 5 to 8 liters per min. at 4 bar

- Cooling capacity: 1000 watt cooling capacity at 20°C

Applications In

-

Food

Textured vegetable proteins, structured meat alternatives, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products, and many more

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project