Diverter Valve

Improve Startup Efficiency and Safety

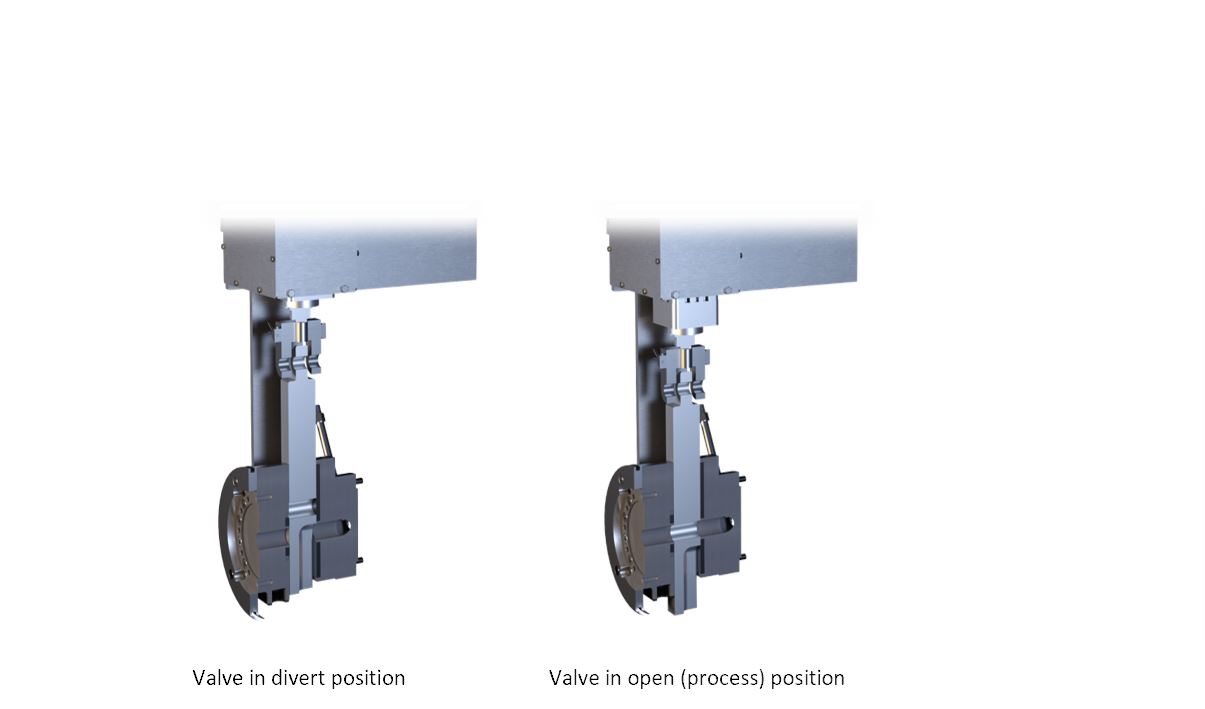

The Wenger Diverter Valve provides an effective and convenient way to divert wet material during the start up phase. This is especially helpful for textured protein applications.

When the material quality and characteristics have been reached, the valve can be easily shifted to the open (process) position which provides optimal pressure and flow to the die.

- Small size, no removal cart needed

- Allows the process to reach a "kill temperature" before product is sent to the die

- Valve is engineered for simplicity and low maintenance requirements

- Bolt-on connection

- Stainless steel construction

- Bottom discharge

- No wet material in knife hood or conveying system

- Enables streamlined product flow

- Includes electric heaters

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project