Steam/Water Mixing Injection (SMI)

Increase Efficiency of your Wenger Preconditioner by Combining Steam and Water into a Single Injection Process

The Steam/Water Mixing Injection (SMI) system was created by Wenger to provide a more efficient preconditioning process with reduced maintenance.

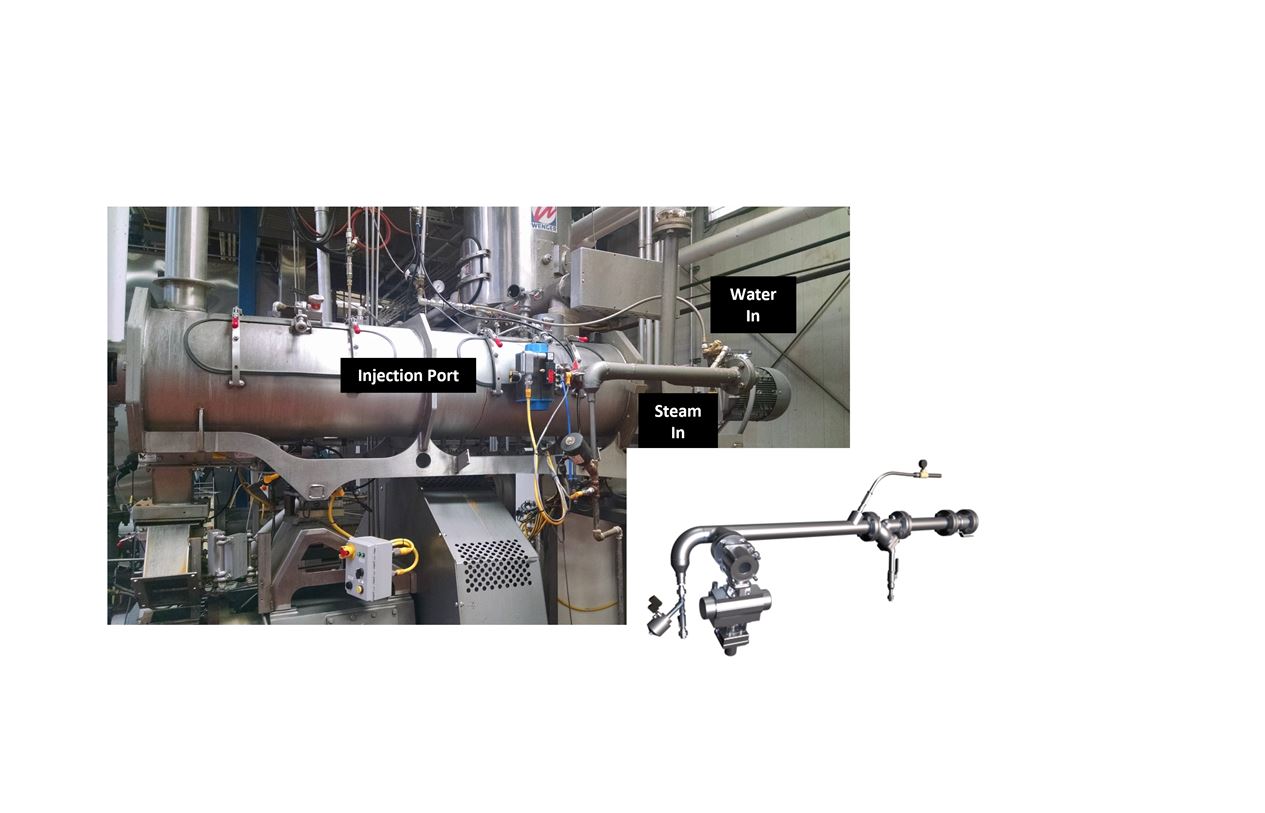

The SMI can be retro-fitted to an existing Wenger HIP or HSC preconditioner models, or specified on new equipment. Water and steam are combined together and injected into the preconditioner via a single injection port with a surface mounted valve.

By simplifying the steam and water injection process, the SMI is yet another Wenger innovation that not only solves challenges (such as plugged injectors) but enables more consistantly mixed and cooked product entering the extruder.

Benefits of the SMI

-

Single injection port eliminates manifold, valves, pipe/hoses, and multiple injectors. This reduces maintenance, replacement parts, and cleaning requirements

-

Reduces potential for injector plugging

-

Higher cook values off preconditioner at same steam and water inclusions

-

Significant reduction in steam escaping the preconditioner vent

-

Lower product temperatures off preconditioner

-

Increases safety for operators by enabling automated blow-down

-

Automated condensate drain system used during start-up

The SMI is available on these Wenger preconditioners

Applications In

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project