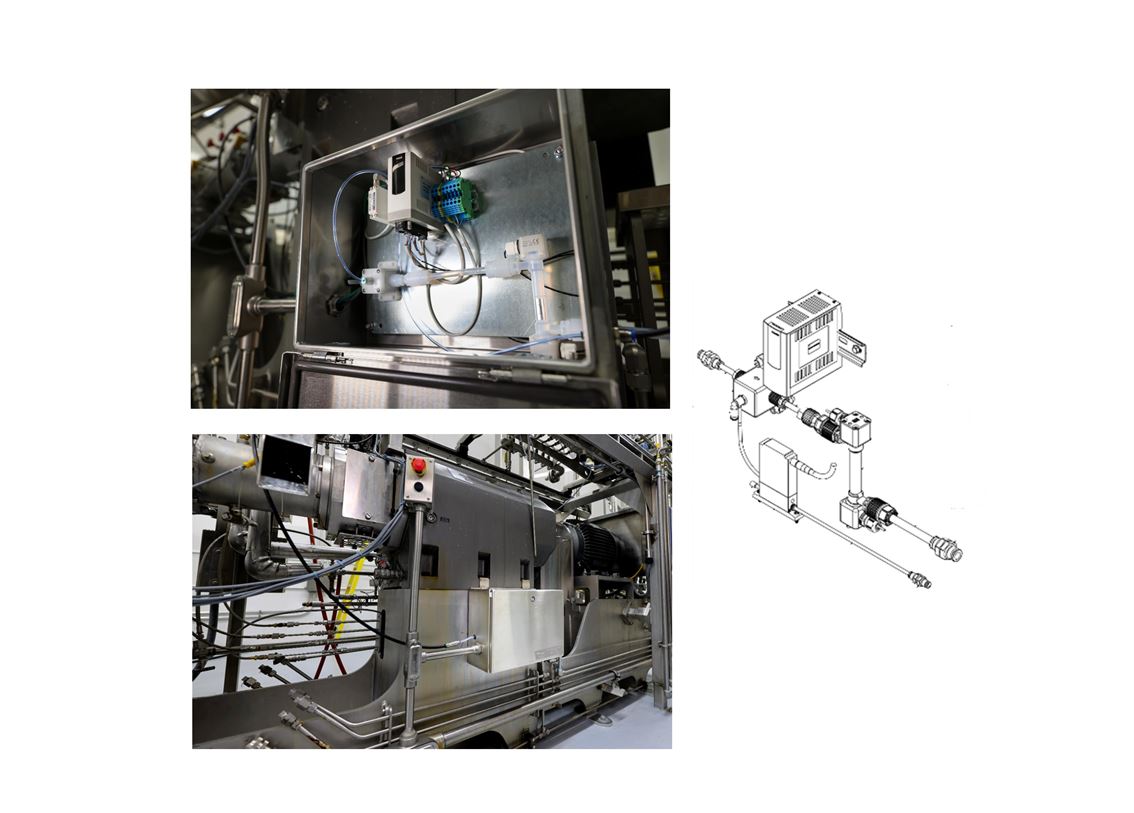

EXact™ Water Flow Control

Improve accuracy of water volume into your Wenger extruder or preconditioner with the EXact™ Water Flow Control system.

- Provides operators with very precise flow control

- Ideal for lower flow applications

- Mounts at the extruder rather than in the plumbing rack

- Reduced line length requirements for steady flow

- Uses a sound tube and diaphragm for control of flow, from 5.0 kg/hr to 150 kg/hr at 60 PSI

- Voltage: device 24vDC; analog control 0-10vDC

- Components are CE certified

-

P/N 055443

How it Works

An ultrasonic flow meter determines the flow and transmits a signal to a controller, which compares the flow rate to the setpoint and sends the appropriate signal. An electro pneumatic regulator converts the electric signal to an air pressure, which actuates an air operated diaphragm valve to vary the flow.

EXact water flow control is an effective and economical way to improve accuracy of water into your Wenger equipment.

Applications In

-

Food

Textured vegetable proteins, structured meat alternatives, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products, and many more

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project