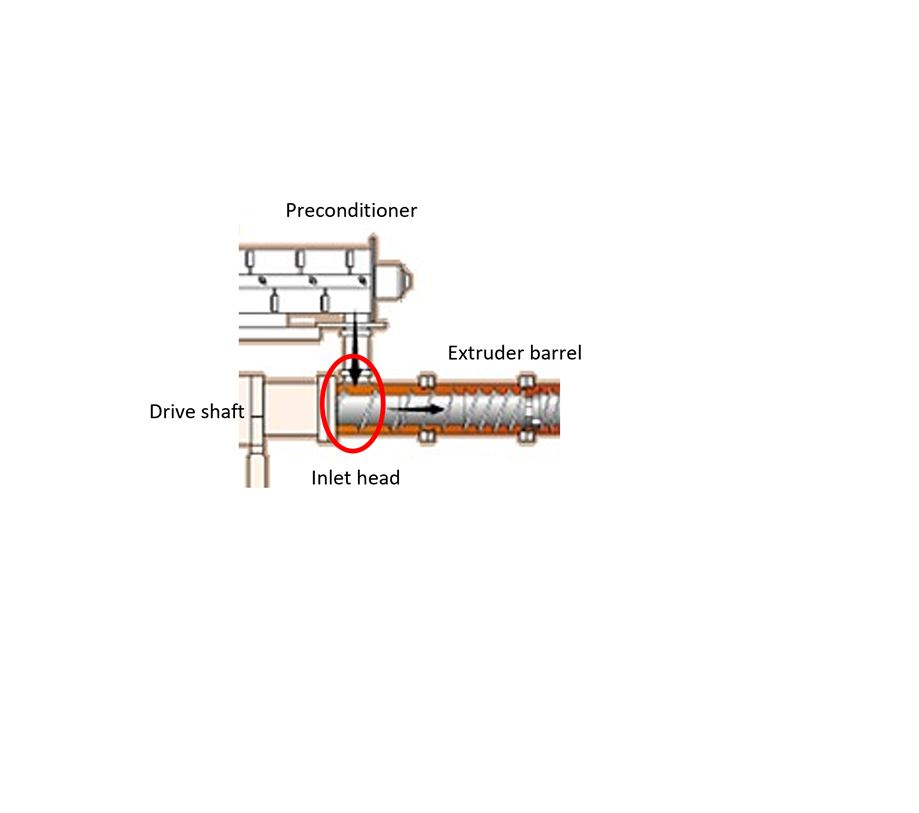

Inlet Head Assembly with Extended Wear Seals

Upgrade the Shaft Seals on your Single Screw Extruder

Inlet head seals play a vital role to ensure material moves through the extruder barrel properly. Over time, older-style seals that contact inlet screws can become worn and could allow material and fluids to flow backward toward the drive shaft. Improper sealing not only results in a loss of valuabe product, but could create other mechanical problems including frequent replacement of standard seals.

Wenger offers an extended wear inlet seal assembly (P/N 63525001) that provides significantly longer wear life for seals compared to older-style inlet assemblies. In the upgaded assembly, the seals are seated on the extruder shaft and do not contact product or the inlet screw. Made from high quality composite material, the upgraded seals also offer a high level of corrosion resistance. The new seal assembly requires an upgraded inlet screw and a new head spacer.

This simple, econonmical upgrade can improve your operations, extend the life of your extruder, and reduce maintenance costs and downtime. Don't let a worn inlet seal interrupt your operations. Contact Wenger at +1 785 284 2133 and ask about our inlet head assembly upgrade.

Note: Two (2) seals are required on the inlet head

Applications In

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project