PetFLEX™ Twin Screw Extruders

The Most Flexible Extruder Ever for Pet Food Production

Process traditional kibble, high fresh meat products, grain-free products, unique inclusions, and limited ingredient diets all from one machine - at optimized throughput and quality - with no screw configuration change required

- Two available models: PFX-3000, PFX-600

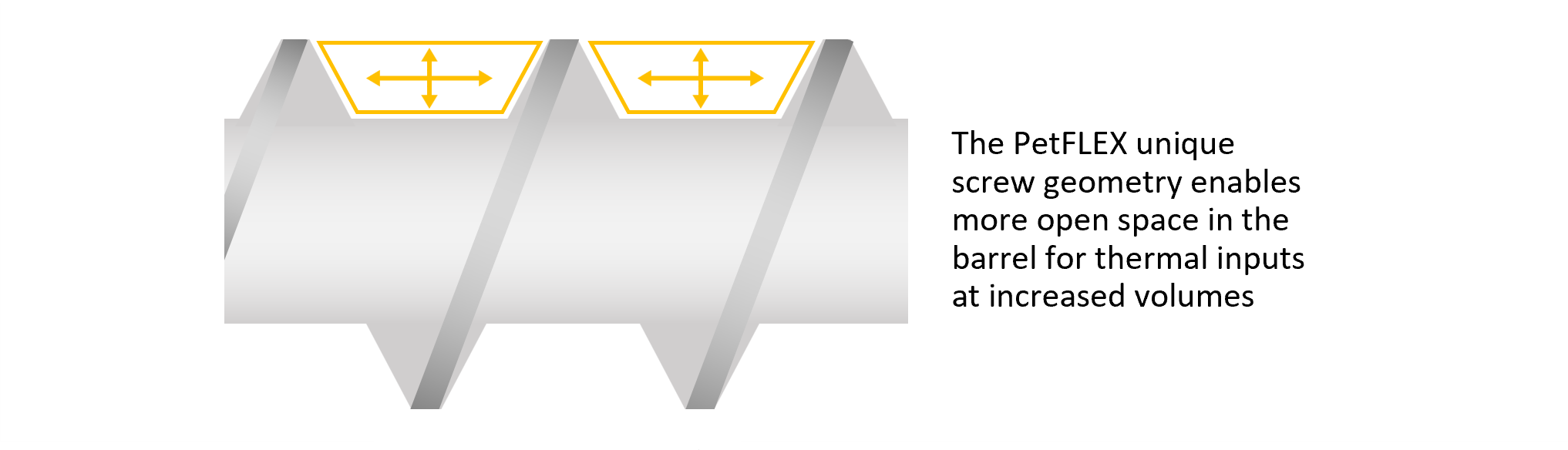

- Unique twin screw design and configuration creates multiple processing zones to optimize thermal energy and mechanical shear inputs

-

Higher volumes through the barrel while maintaining quality - target output can be up to 12,000 kg/hr (PFX-3000)

- Excellent durability - the unique metallurgy along with specially designed rotating elements and barrel results in improved wear life and unmatched system uptime

- Flexible to accommodate alternative and unconventional ingredients

-

The intuitive design simplifies operation, making it easier for technicians to learn and master the system

Increased Throughput, Increased Thermal Processing, Better Cooking Efficiency

PetFLEX extruders use a unique twin screw geometry to create larger processing zones that can maximize efficiency of thermal inputs (steam). This enables the PetFLEX to process and cook a wide variety of recipes from the same machine without significant modifications between production runs. The unique screw and barrel design increases available volume which - coupled with adjustable speed control - maximizes overall throughput while maintaining critical quality parameters of starch gelatinization, density, and product uniformity. With a capacity up to 12,000 kg/hr, PetFLEX has the flexibility to produce traditional and premium products at higher - or lower - volumes as needed.

How can one machine do so much? The answer is Wenger FLEXability:

- One screw configuration can be used to produce a wide variety of products

- By coupling with the Wenger HIP, the PetFLEX uses thermal energy and low shear processing to improve the cooking process - this not only saves energy but also enhances product flavor and results in a finished product retaining resistant starch, known for supporting gut health in pets

-

Positive and uniform conveying mechanisms provide flexibility, allowing for uniformity in extrudate regardless of the product type

- The quick response of this machine to advanced process control tools enables faster tuning, stabilization, and refinement of processes - this responsiveness allows it to achieve consistent product quality faster, with fewer trial-and-error adjustments

- The heavy-duty gearbox is designed to manage both high SME (for energy-intensive products) and low-shear processes (for more delicate applications)

- The machine can operate at higher or lower volumes without significant adjustments to maintain consistent quality

- PetFLEX components are designed and manufactured to be extremely rugged and durable - typically requiring less maintenance and replacement than those in other extruder designs

- Can be used to produce high volumes of any type of feed. For aquatic feeds, including micro size feeds, this technology is available with the Wenger AquaFLEX extrusion line

Performance

| MAX CAPACITY (KG/HR) | MOTOR SIZE (HP) | |

|---|---|---|

| PFX-3000 | 12000 | 300-600 |

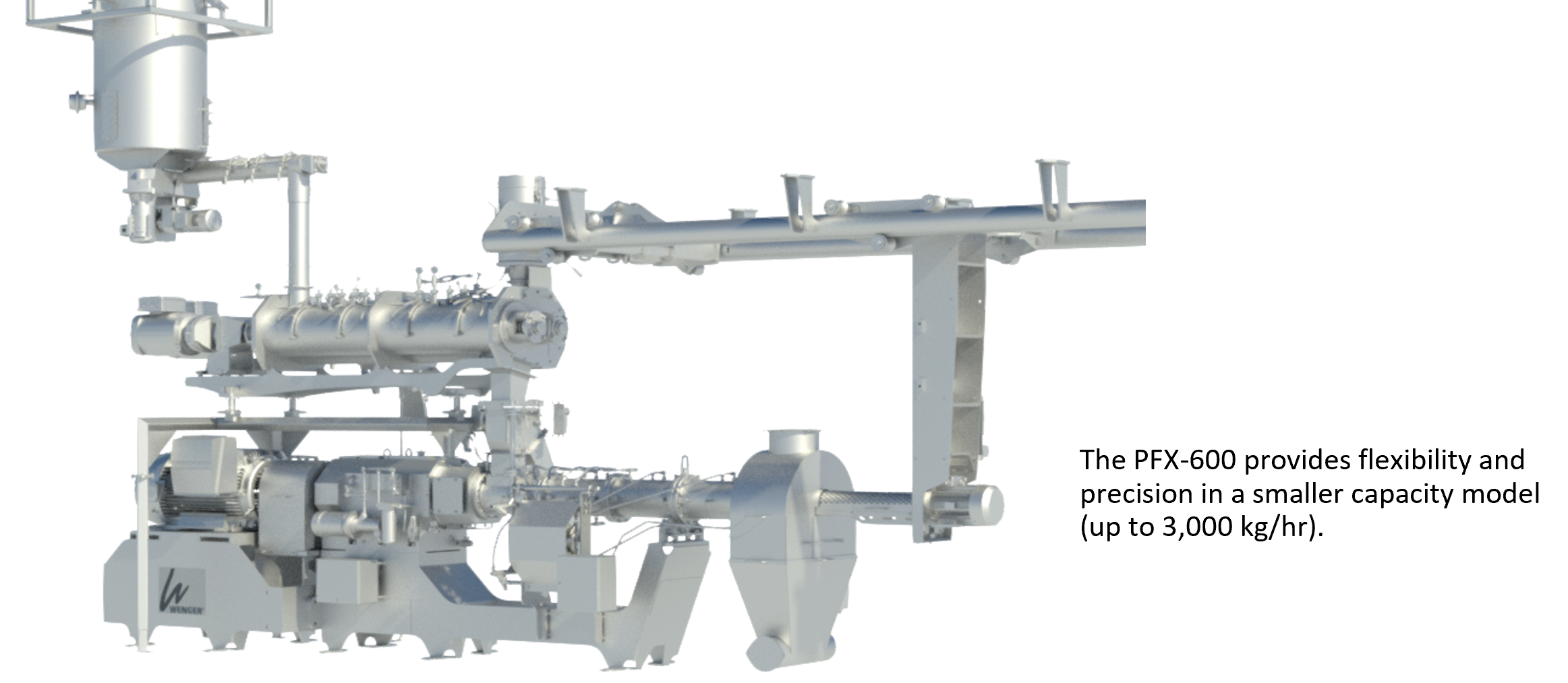

| PFX-600 | 3000 | 150 |

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project