Pet FoodMAKE FOODS AND TREATS THAT PETS LOVE TO EAT

-

Product Flexibility

Produce organic, functional and other on-trend products

Create unique textures and appetizing results

-

Unlimited Options

Soft bites, unique shapes, varied sizes and applications

Create all types of treats that are popular with pets and pet parents

-

A Proven Leader

Continuous innovation and industry influence

Groundbreaking ingenuity recognized around the world

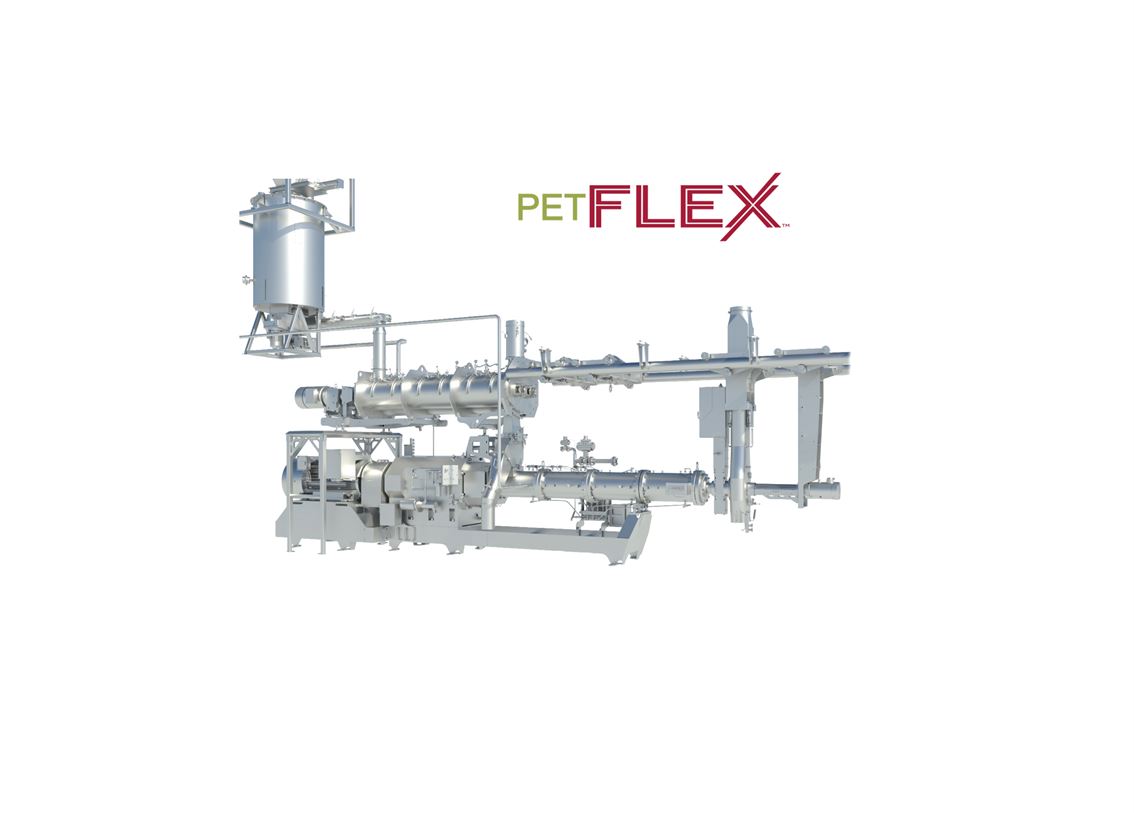

PetFLEX™ Maximum Flexibility for Pet Foods

Wenger's PetFLEX extruders use a unique screw configuration to create processing zones that allow for the optimal balance of shear and thermal energy transfer. This results in stable, uniform production of a wide variety of foods and treats -using traditional and novel ingredients - without “surging” that often happens with single screw designs. PetFLEX also enables fresh meat inclusion as well as other inclusions to improve nutrition, palatability, and visual appeal.

For more detail about PetFLEX, click here

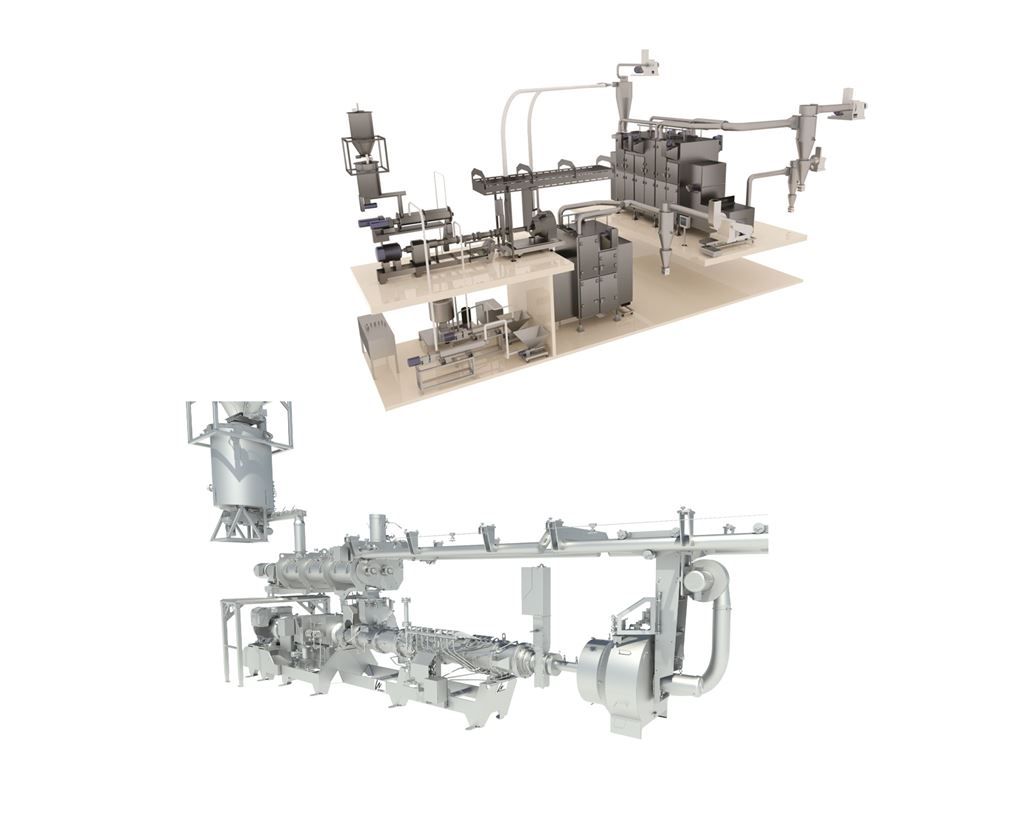

Produce High Fresh Meat Content Pet Foods and Treats with the Thermal Twin

Wenger's Thermal Twin extrusion technology is the most effective and proven system to produce kibble with high fresh meat inclusion.

The Thermal Twin's creative screw geometry, along with an innovative method of high steam injection, allow recipes to be cooked more gently - in a thermal manner – as opposed to an aggressive high shear method found in traditional extruders.

Post extrusion, the Wenger process utilizes specially designed die hoods and takeaway conveyors to preserve the quality of the fragile kibble. The patented Convection Roaster (CVR) begins drying while continuing the gentle thermal cooking process. These actions strengthen the kibble so it can survive future processing steps, and help create a highly palatable product.

Pet foods with high levels of fresh meat used to be considered very difficult to manufacture on a large scale. Now they are commonplace in the global market thanks to the Wenger Thermal Twin System.

Auto Density Control

Auto Density Control integrates three existing process components to provide automatic control of wet bulk density. It automatically measures product density and adjusts the process to maintain the desired density specifications.

- Programmed to collect and analyze a sample as often as 45 seconds

- Automatically adjusts the process to reach a new density setting in as little as 2 minutes

- Decouple personnel from the product for greater food safety

- Provide validation data for the process via the data display and recording capabilities of the system

Auto Density Control consists of three basic components:

- Source Technology sampling and bulk density measuring device (BDS)

- Wenger Automated Process Management (APM) system

- Wenger Back Pressure Valve (BPV) mounted on the end of the extruder to control specific mechanical energy input

- Auto Density Control can be installed as part of a new system or retrofitted into a system that already has at least one of the basic components.

Pet Treats

There are five basic categories of pet treats that can be produced using Wenger extrusion technology:

- Expanded Treats

- Un-Expanded Treats

- Extruded Filled Treats

- Co-extruded Treats

- Chews (including dental care)

Unique Shapes? Colors? Fills? No problem.

Whatever type of treat you're looking to make, Wenger's process experts can help you understand how to create it using proper extrusion cooking and drying processes. This includes Wenger's unique knowledge of simultaneous, multi-color extrusion, and unique shaped dies to achieve the product you (and your customers) expect - with consistent quality.

With Wenger, you make nutricious and delicious products that pets (of all sizes) love to eat. And eat. And eat.

Through careful testing and extensive research, our world-class team helps you develop premium foods and treats, and the processes to produce them at scale.

Pet food producers globally trust Wenger for extrusion cooking and drying solutions to satisfy healthy pets everywhere.

Contact Wenger and see how we can help you.

Extruders

-

FRESH MEAT INCLUSION

Pet food consumers are demading options for increased levels of fresh meat. Wenger systems can help you achieve consistent production of foods with very high fresh meat content.

-

PERFORMANCE AND FLEXIBILITY

Whatever type of pet food or treat you want to create, Wenger has an extrusion system - and the process knowledge - to make it a reality.

-

INGREDIENT VERSATILITY

With Wenger systems, you have the ability to change ingredients and recipes wihtout major reconfiguration of your extruder setup.

-

EQUIPMENT SIZES TO FIT YOUR NEEDS

Whatever your target output level is, Wenger has an extruder and dryer system that can meet your production and budget requirements.

Request Info

to discuss the feasibility, design and implementation for your project

Research & Product Development

The Wenger Technical Center is an agrifood laboratory equipped with the latest in research and production scale extrusion and drying equipment. Let us assist you with:

- Product development

- Laboratory analysis

- Process evaluation

Project Feasibility, Design & Implementation

Count on our knowledge base and breadth of experience that is unsurpassed in extrusion processing and facilities construction.