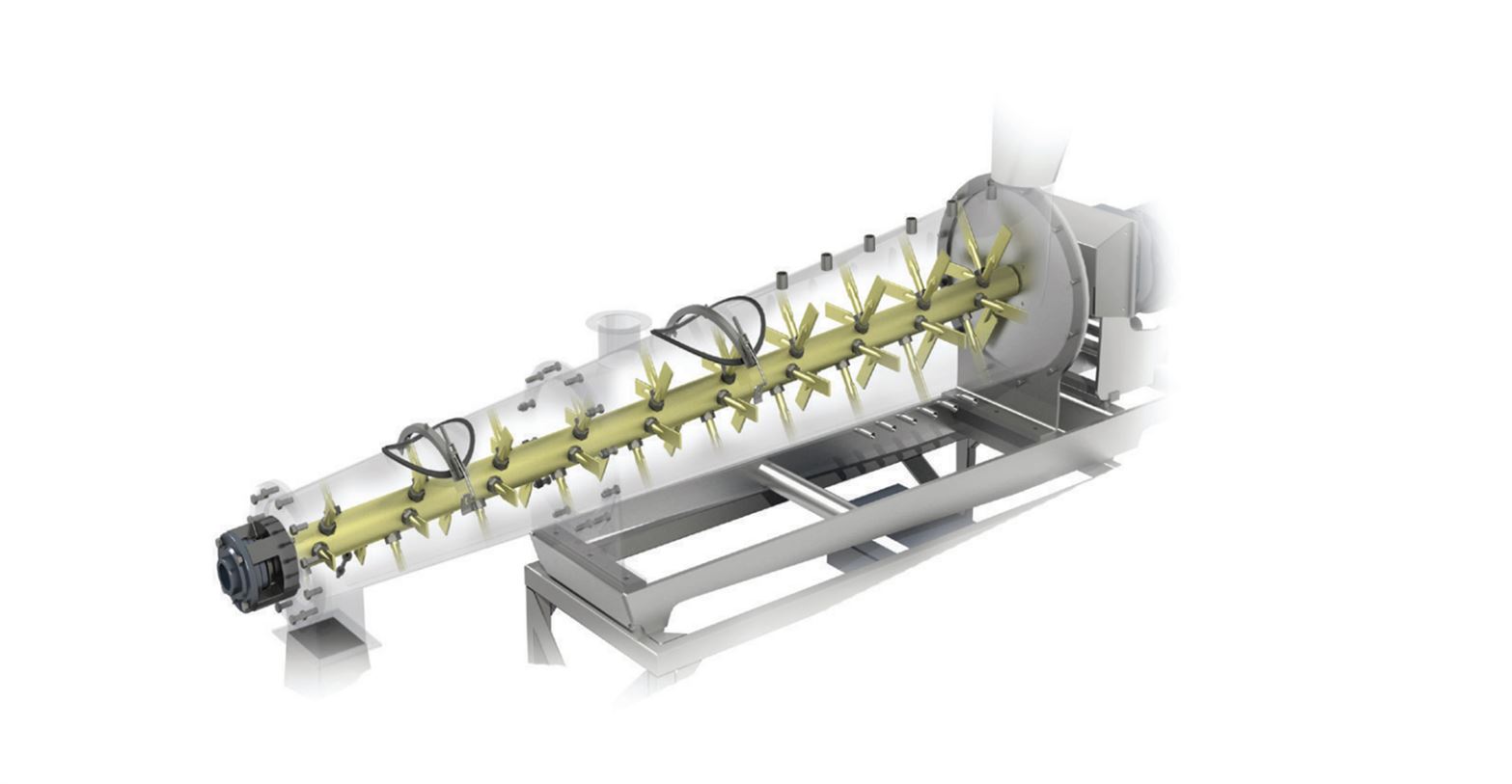

High Shear Conditioner

The Wenger High Shear Conditioner (HSC) is the perfect complement to the AquaFlex XT

- Single shaft tapered design - engineered primarily for aquatic feed production

- Steam-Water Mixing Injection (SMI) combines steam and water into one process flow stream - enabling higher cook values from the preconditioner vs. standard injection

- Increased sheer as feed travels from high volume inlet to lower volume outlet

- Faster penetration of heat and moisture into the feed particles

- Elevated mixing intensity results in 85% to 90% gelatinization of the starch in microground shrimp food formulas at 4,000 to 5,000 kh/hr

-

Increased beater contacts - up to 30,000 per minute

-

Capable of high discharge temperatures of >90 deg. C

-

Single drive motor provides energy savings

-

Reduced number of components lowers maintenance costs

-

Equipped with VFD which enables process adjustments

Although the High Shear Conditioner was designed for aquatic feed production, Wenger has successfully employed this technology in other extruded feed applications. Contact us to discuss if the HSC could be a good fit for your operation.

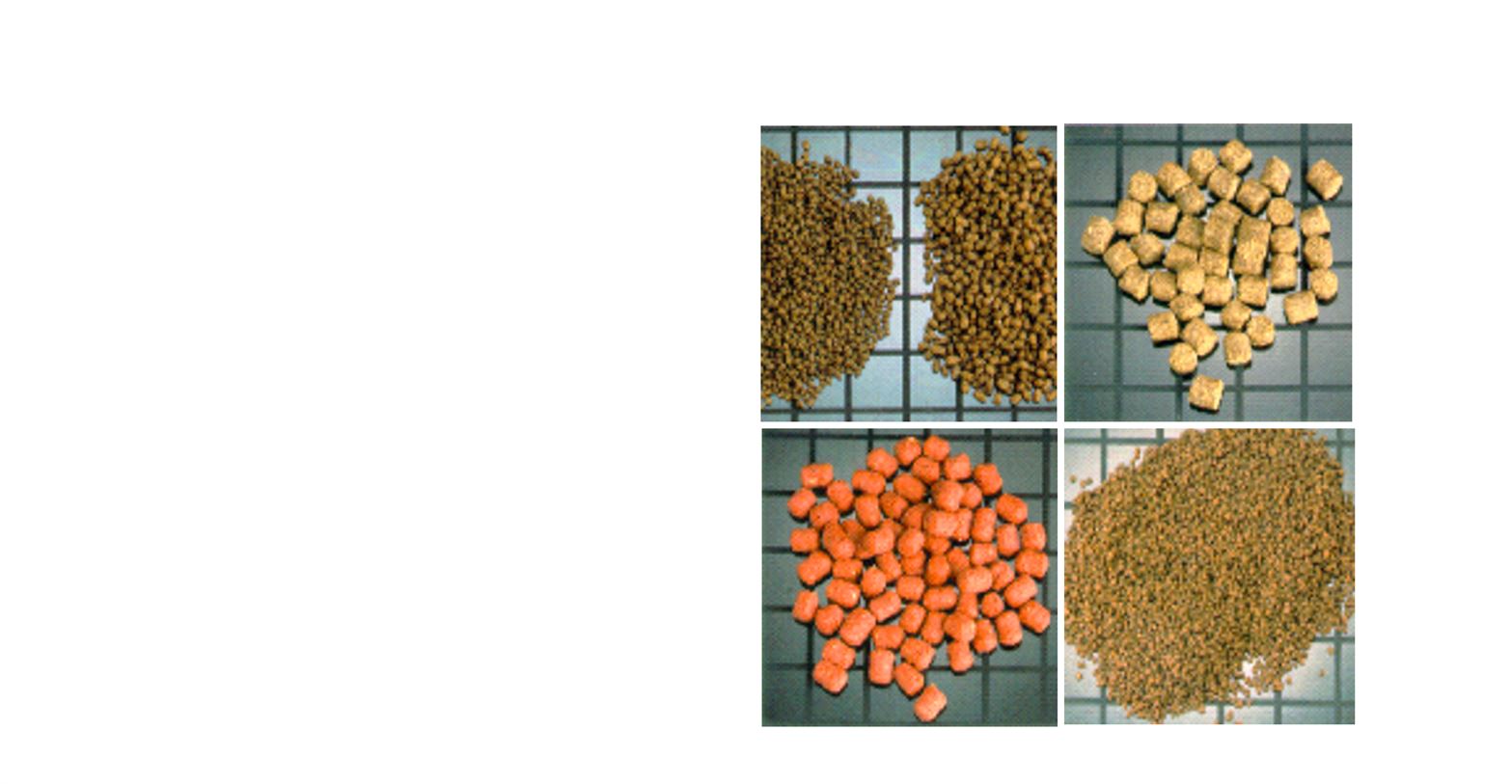

Products that Benefit from the HSC:

- Low fat floating and sinking aquatic feeds

- High fat floating and sinking aquatic feeds

- High fiber aquatic feeds

- Shrimp feeds

- Micro feeds (0.6 mm – 1.2 mm)

- Traditional kibble

-

AVAILABLE MODELS

HSC570 1,000 – 5,000 kg/hr

HSC1120 5,000 – 12,000 kg/hr

HSC2100 12,000 – 20,000 kg/hr

HSC3150 20,000 - 30,000 kg/hr

Applications In

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project