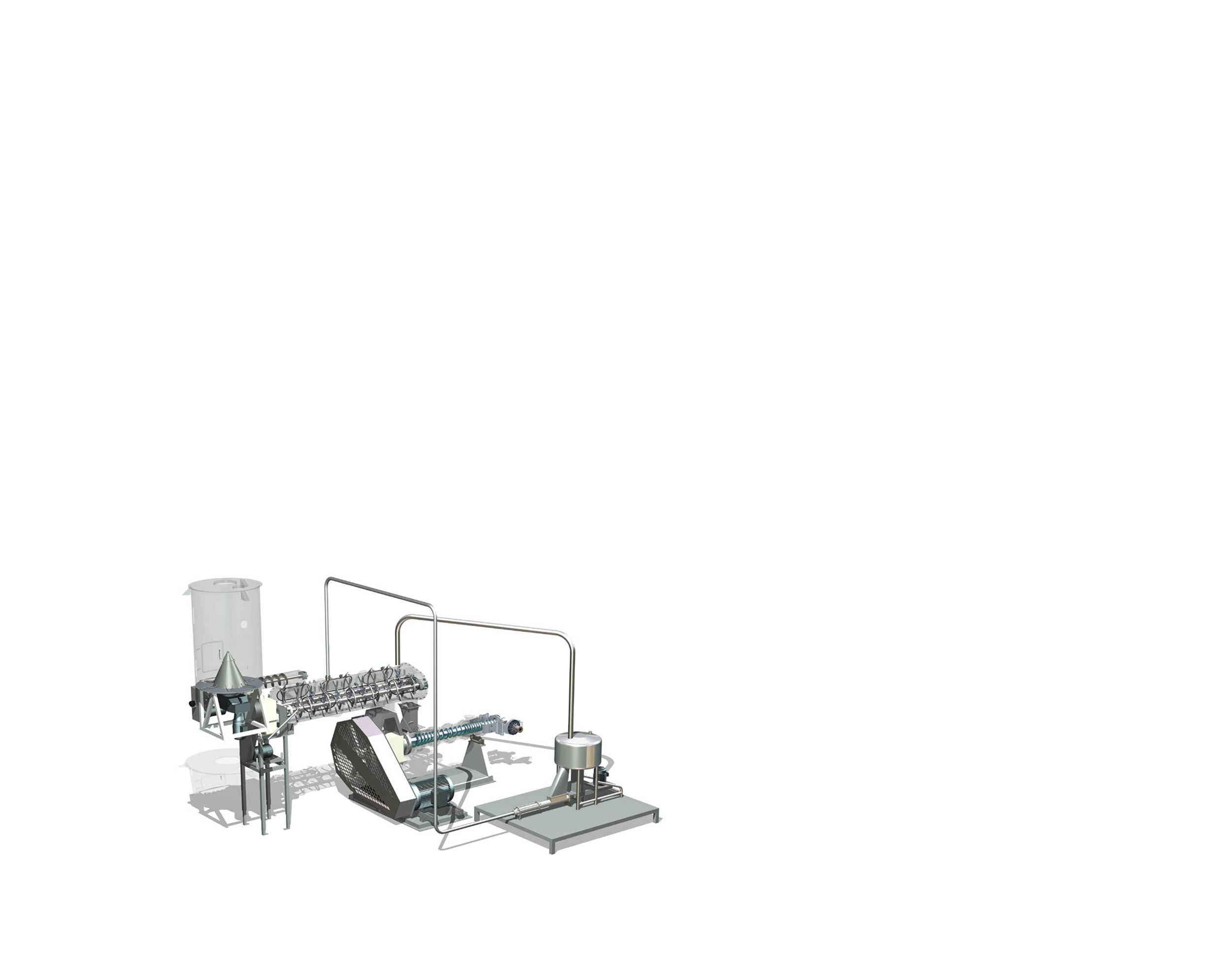

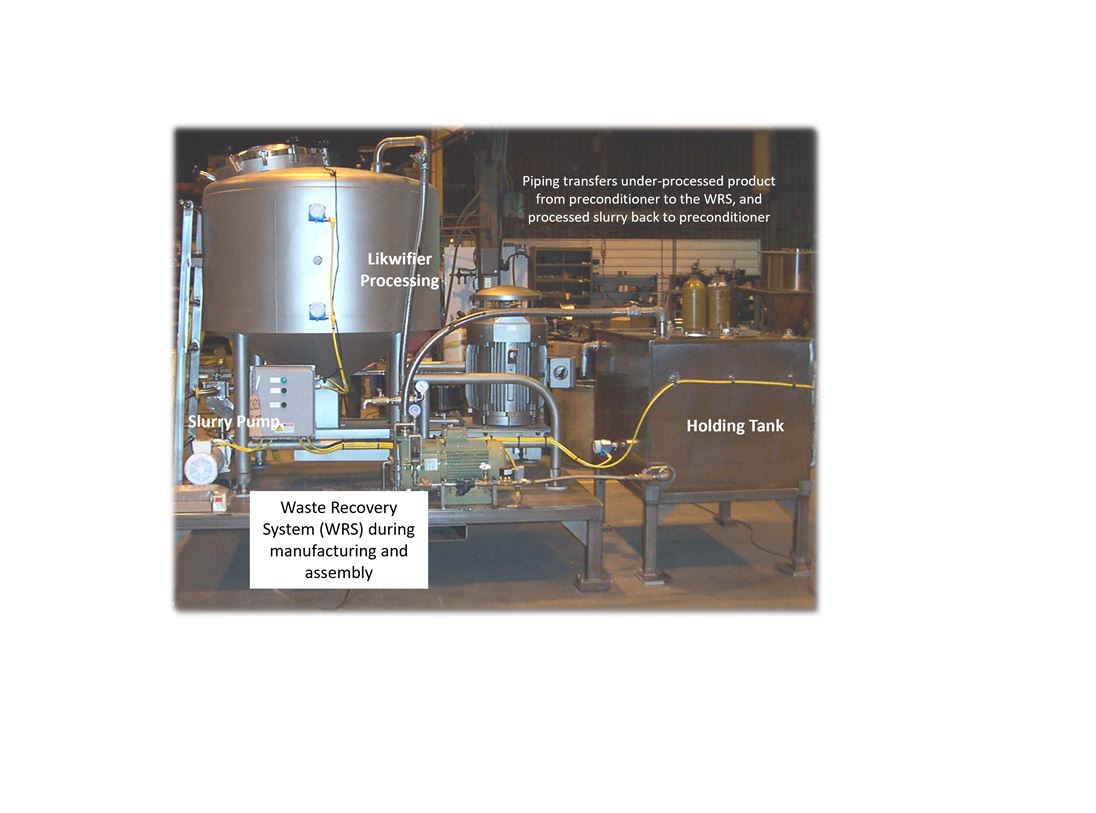

Waste Recovery System

Reduce Costs and Avoid Re-contamination by Reclaiming Startup/Shutdown Product

Wenger's Waste Recovery System (WRS) reclaims wet, under-processed product that cannot be recycled through the dryer as dry re-work. In some instances, the savings for energy, water, and product can easily total more than $100,000 annually.

- Wet, under-processed product from extruder/preconditioner startup/shutdown is reclaimed and added back into the process, eliminating the need for off-premise disposal

- Improve housekeeping in extrusion area by collecting fines discharging from the preconditioner

- Improve operator comfort by reducing steam and product fines discharging from preconditioner

- Extend life of preconditioner bearings and seals by removing excess steam in the preconditioner

- Generate hot water for liquefying step, process water, or other unit operations

Wenger also offers a "mini" WRS for capturing emissions from the preconditioner vent, preventing a possible source for contamination.

Applications In

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project