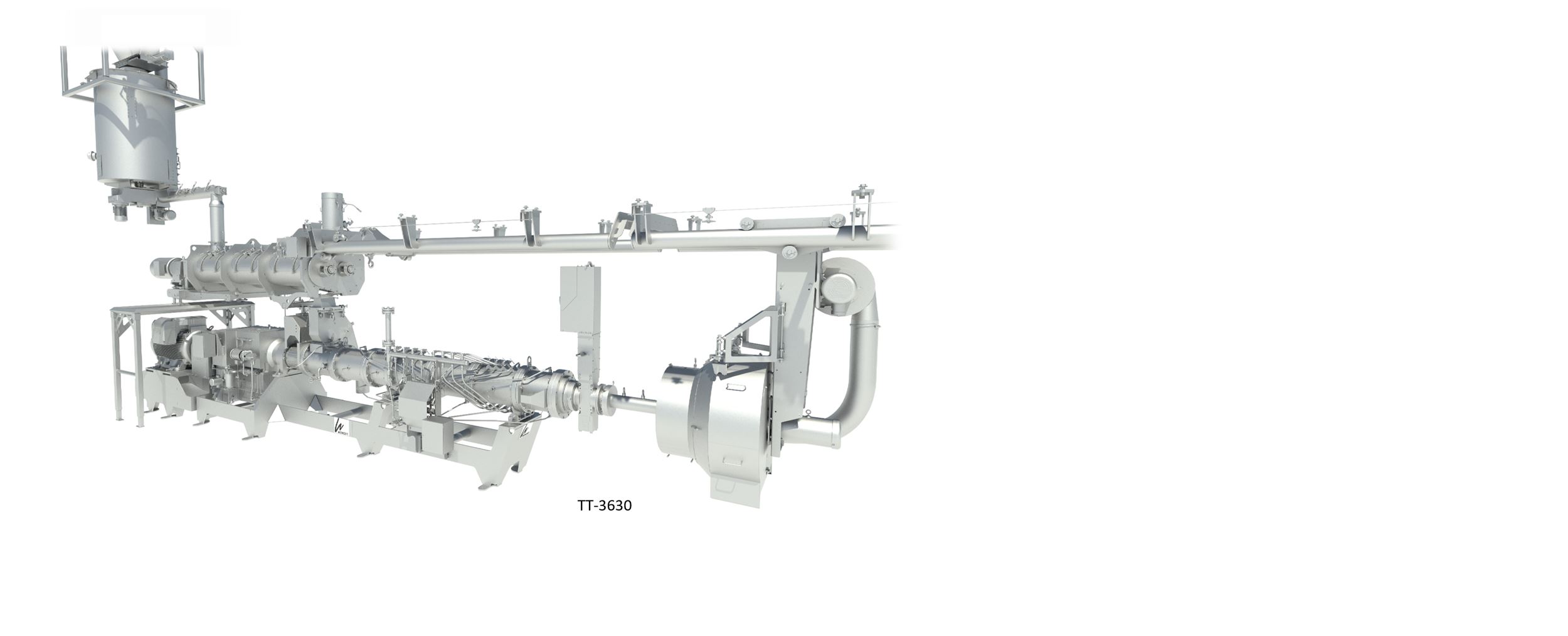

Thermal Twin Twin Screw Extruders

The premier solution for premium pet foods - especially those with high levels of fresh meat inclusion.

Wenger Thermal Twin Extruders remove product barriers and allow industry innovation by creating a new energy source through the increased use of steam injection.

- Angled steam injector ports oriented in the direction of material flow

- 4x more steam injection into extrusion zones

- Up to 12% steam injection evenly distributed over the length of the barrel

- 14:1 thermal to mechanical energy ratios

- Operating costs nearly equal to single screw technology

Testing of Thermal Twin technology has consistently yielded products with more than 90% cook compared to values in the 80s when the same products were processed on conventional extruders - with no change in product density or palatability.

Thermal Twin Benefits

- Less costly energy source (vary input ratio of thermal to mechanical energy) – Lower SME

- Lower wear costs compared to other twin screw systems

- Less sticky products due to low shear

- Ability to achieve higher meat and other slurry levels

- More “natural” cooking (thermal energy) leads to development of new products

- Lower vitamin and trace mineral destruction

-

High Intensity Preconditioner

The Wenger High Intensity Preconditioner (HIP) provides a level of mixing intensity that makes it the perfect complement to the newest Wenger extruders.

- Two independently driven shafts offer speed and rotational direction control

- Wide range of capacities and retention times

- Three mixing intensity settings

- More uniform hydration and heating of the recipe

- Allows increased addition of meat slurries and other liquids in the recipe

-

Automated Mixing Intensity Control

- Load cells take control of the process, including startup, shutdown and cleanout modes

- Controls for temperature, moisture and shaft speed

- Helps reduce waste at both startup and shutdown

-

Food Safety

- Stainless steel hygienic frames and constructed with minimal seams for improved hygiene

- Less horizontal surface area for product accumulation

- Dust-tight downspout reduces fugitive dust in the transition from preconditioner to extruder

- Hygienic Pneumatic Hood comes equipped with sampling port and sight glass for no-touch monitoring

Performance

| Model No. | Max Capacity (kg/hr) |

|---|---|

| TT-760 | 2400 |

| TT-3630 | 10000 |

Applications In

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project