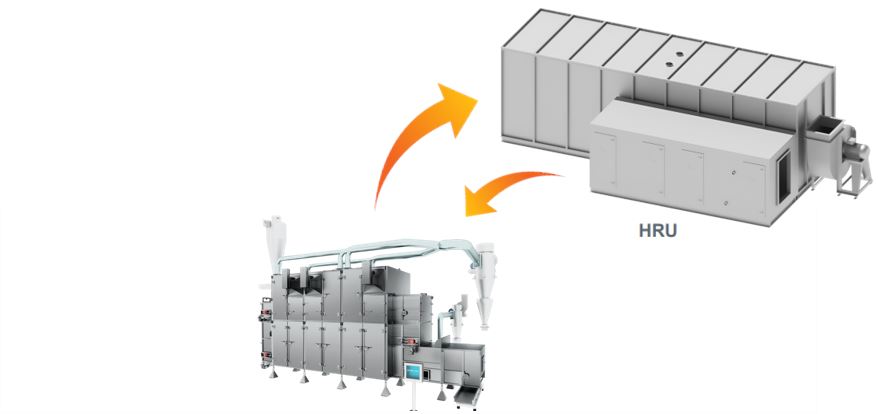

Heat Recovery Unit

Achieve up to 25% energy savings by recuperating exhaust air from Wenger dryers

Wenger's customized options can help you achieve your sustainability goals

√ Air Cleaned √ Odor Reduced

√ Water Reclaimed √ Energy Recovered

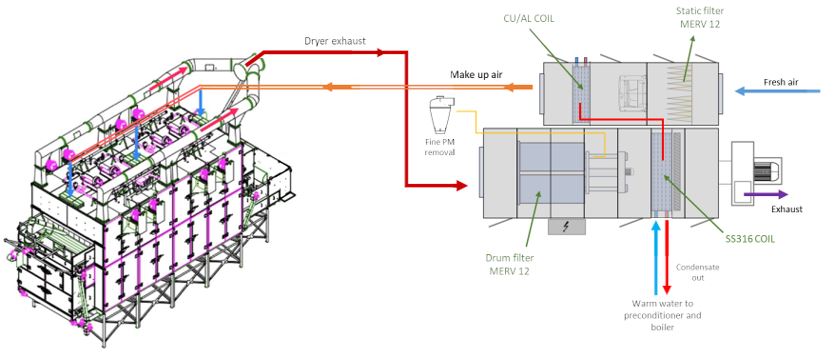

- HRU connects to dryer exhaust and provides recuperated make-up air back to dryer

- Uses proven technology - interconnected air-water heat exchangers

- High efficiency drum filtration to capture fine particulate

- Effectively reduces odor

- Recovers water condensate

- Energy savings leads to rapid payback

- Expandable platform for further energy savings

How It Works

Adding a Heat Recovery Unit to your Wenger dryer is an excellent first step toward reducing energy consumption while maintaing proper energy transfer within the dryer, and without a significant increase in physical space requirements. In some situations, it may be possible to install one HRU to function with more than one dryer, achieving greater savings.

Additionally, adding a high temperature heat pump along with the HRU enables reduction - or complete omission - of carbon emissions, improved fuel flexibility, and decreased energy costs. Contact Wenger for more information about effective and sustainable solutions for decarbonizing horizontal dryers.

Applications In

-

Food

Textured vegetable proteins, structured meat alternatives, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products, and many more

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

-

Industrial

With Wenger systems, you can create new products for industrial or consumer applications. Whatever idea you're thinking about, Wenger can help.

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project