Joe Wenger and his brother Lou form the Wenger Mixer Company in the midst of the infamous “Dust Bowl” that ravaged American farms. To aid their fellow farmers, the Wenger brothers “imagineered” a breakthrough grinder-blender system that added molasses to low-value roughage, providing desperately needed cattle feed. And an industry is born.

A History of Innovation

Pioneering the Field, Launching an Industry

An early Wenger portable mixer

Building on their breakthrough high

molasses feed mixer, the Wenger brothers

introduced another innovation — the first

portable feed mixers.

our History

-

1935

Following a devastating fire of the original Wenger Brothers Feed Mill in 1931, Joe and Lou quickly rebuilt the mill and were back in business in just over a month. -

1939

Wenger begins extrusion experiments, pressing high-molasses feed mixtures through a die to form pellets.

-

1940s

The U.S. enters WWII and restricts commodity trading. Wenger stops production until the end of the war. In 1945, Wenger is back in business with Joe leading sales at Wenger Mixing and Lou pioneering machinery at Wenger Manufacturing. Known together as “Wenger,” the brothers take on new space and team members to meet demand.

-

Lou Wenger and Oak Smith visit in Lou’s office during a Wenger Open House in 1955. 1955Master salesman Oak Smith joins Wenger as Sales Manager. Oak’s vision of Wenger technology helping solve world hunger plants the seed for our future charity work.

-

1958

Wenger revolutionizes the industry a second time by inventing the cooking extruder, an innovation that forever changed both human and pet food production.

-

1960

Wenger extends innovations into smaller extruders ideal for the pet food industry and pioneers food safety for human food applications, such as breakfast cereals.

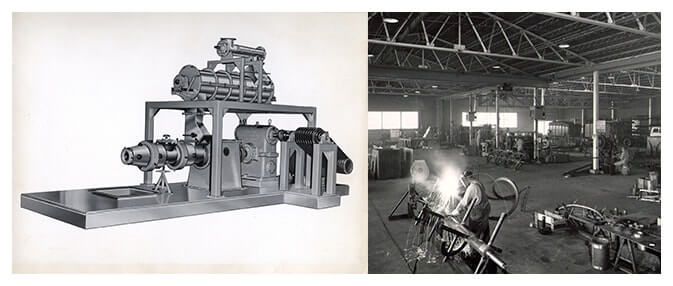

An extruder from the 1959-60 product line designed specifically for human food applications (left); production in full swing at the Wenger plant in 1963 (right). -

1965

The Wenger Technical Center opens and becomes the largest extrusion research lab in the industry, spurring innovations across pet, aquatic and human foods.

-

1969

Wenger begins its decades long collaborations with research universities to advance food technologies, beginning with Kansas State University and the University of Nebraska, and eventually Purdue University, the University of Maryland and others.

-

1970s

1970sWenger partners with UNICEF to formulate the world’s first extrusion-cooked, fortified food to feed hungry children in developing countries. The efforts culminate in Grains of Hope, a partnership between Wenger, Sabetha High School and the Daily Bread Foundation, to target hunger issues in Mozambique.

-

1973

Wenger diversifies into new industry segments including snacks and textured vegetable proteins. Wenger creates the world’s first textured soy protein, which eventually caught global attention as consumers sought healthier alternatives to meat in the 1990s.

-

1977

Joe and Lou promote their sons, LaVon and Don, to the roles of President and Vice President, respectively. Joe and Lou continue in their roles on the company’s Board of Directors

-

1980

Wenger presents its innovative “cook test” to the Institute of Food Technologists and the American Association of Cereal Chemists. Today, iterations on this evaluation are used around the world.

-

1985

1985NASA and the American Institute of Baking approach Wenger to solve experimental food for animal testing in space. In 1990, the Space Shuttle launches with Wenger-made “rat bars.”

-

1985

Wenger introduces the twin screw extruder, which soon dominates the international extrusion cooking market, especially for food applications.

-

1993

Founder Joe Wenger passes away, and is followed in 1995 by his brother and lifelong collaborator, Lou. 1995 also sees the passing of their trusted team member Oak Smith.

-

2000

More than 80 percent of the world’s pet food is manufactured using Wenger Group extruders.

-

2008

Two generations of Wenger leadership: Jeff Wenger, Don Wenger, Lafe Bailey, Brad Wenger, LaVon Wenger, Marc Wenger (left to right)

-

2021

The updated and expanded Wenger Technical Center opens in Sabetha, KS. This 50,000 ft2 agrifood laboratory is one of the largest of its kind in the world, with full scale equipment for developing and testing plant-based human foods, pet foods, and aquatic feeds. The facility has segregated areas for human food and pet food, and features world-class digital communication technology, cameras, and remote viewing capabilities.

-

2022

Wenger is acquired by Marel, a global provider of advanced food processing systems, software, and services. The acquisition enabled Marel to establish a fourth business segment called Plant, Pet, and Feed - alongside its existing segments for Poultry, Meat, and Fish.