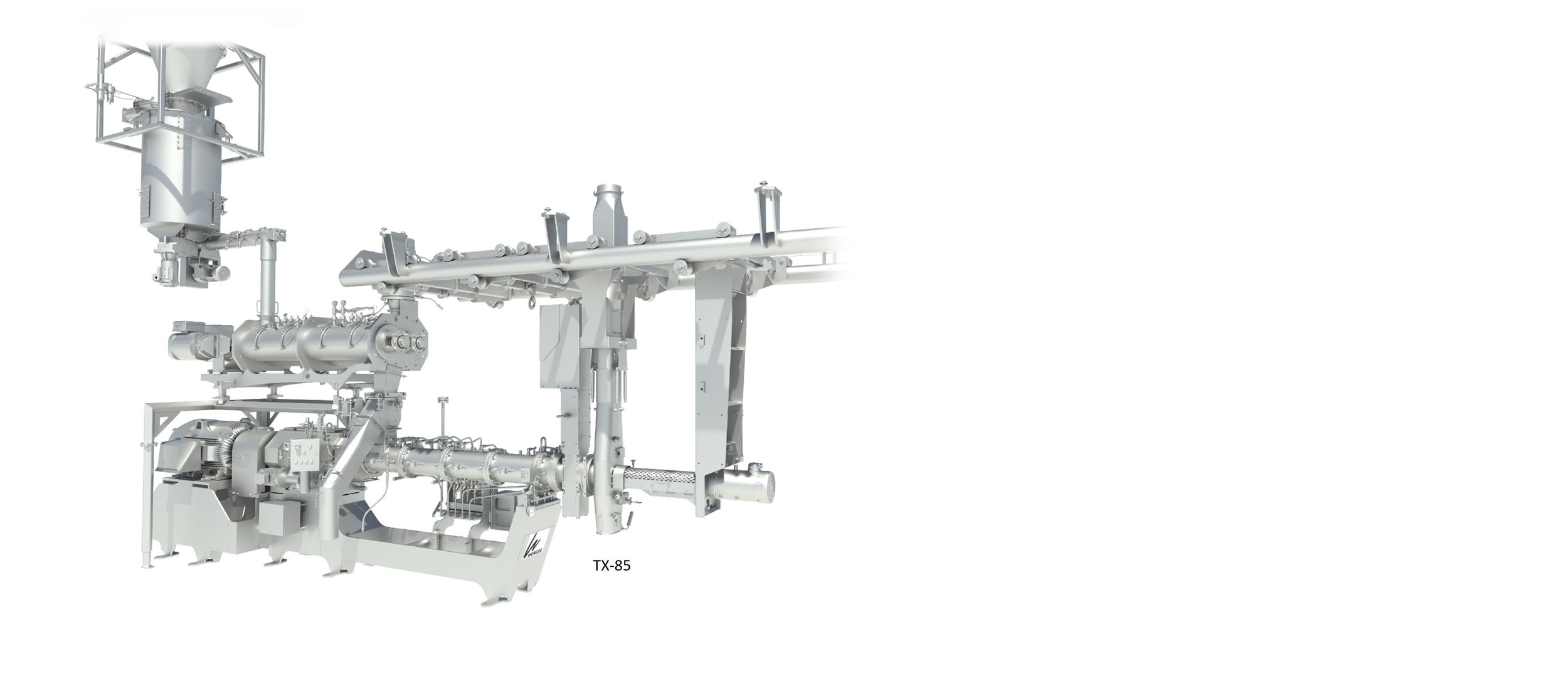

Magnum ST Series Twin Screw Extruders

Wenger pioneered the use of twin screw extrusion cooking in the 1980's. Today, Wenger twin screw extruders can be found all around the world, producing a wide range of delicious and nutritious human foods, snacks, and ingredients; premium pet foods and treats; and high quality aquatic feed.

With Wenger twin screw systems, the possibilities of what you can produce is endless.

High SME Ratings and Unsurpassed Versatility

The Magnum ST Series redefines versatility for cooking extuders. Maximize your output in a smaller footprint. And use the higher SME (Specific Mechanical Energy) levels to take your extruded products to the next level.

- Maximum speeds up to 1,200 rpm

- Power levels to 165 kWhr/t SME at volumetric capacity

How can higher SPE benefit your extruded products?

-

Potential for lower bulk density

-

Higher absorbency levels of liquid coating

-

Smaller cell structure

-

Enhancement of textural properties

-

Higher cook levels

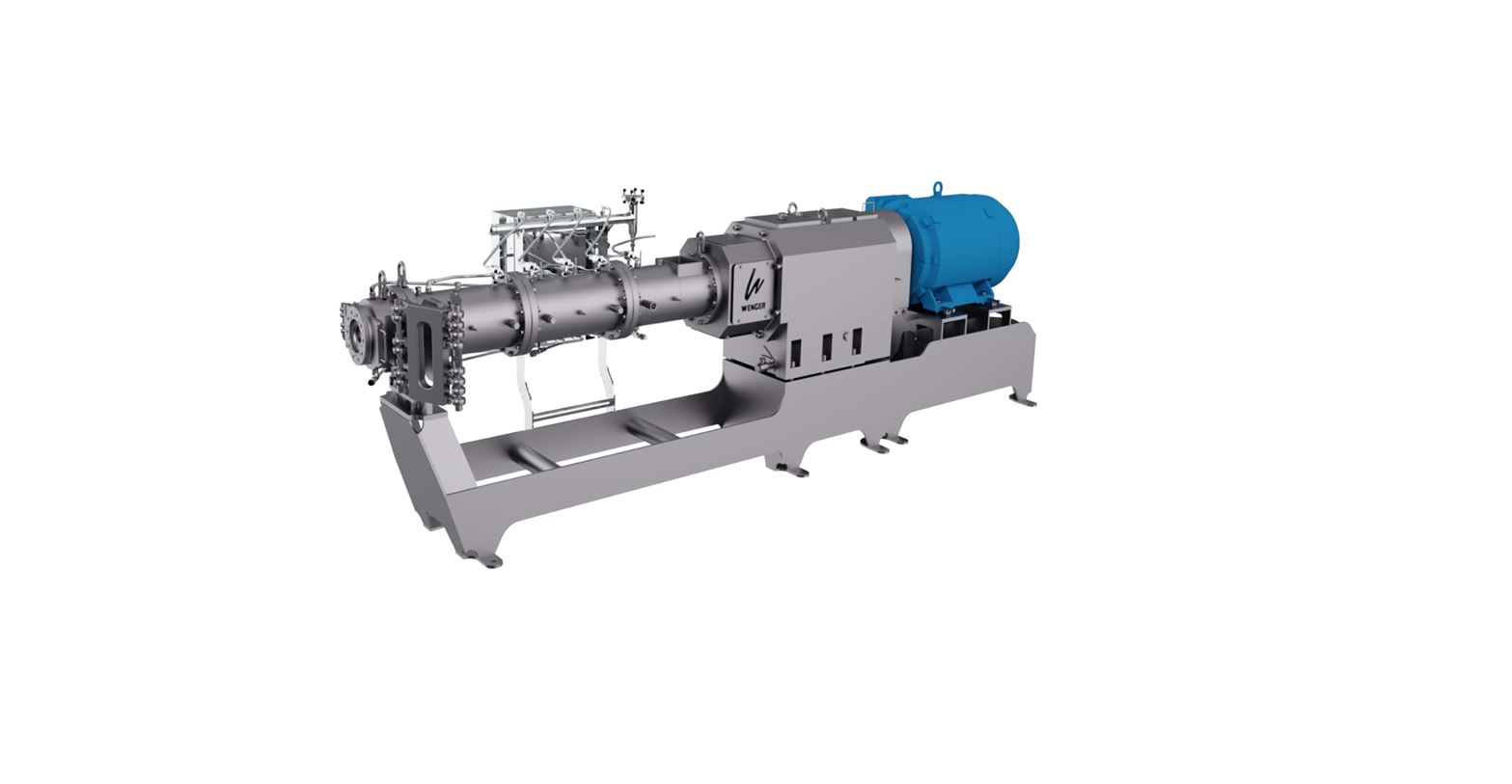

Higher Torque at Lower Shaft Speeds

Utilizing parallel-shaft twin screws, the Magnum ST extruders are ideal for unique processes that require extreme operating parameters. With their increased process flexibility and rate potential, the Magnum ST Series is especially suited for:

- Applications with extreme product viscosities

- Processes requiring high SME inputs

- Continuous physical and chemical reactions

- Dispersive mixing applications

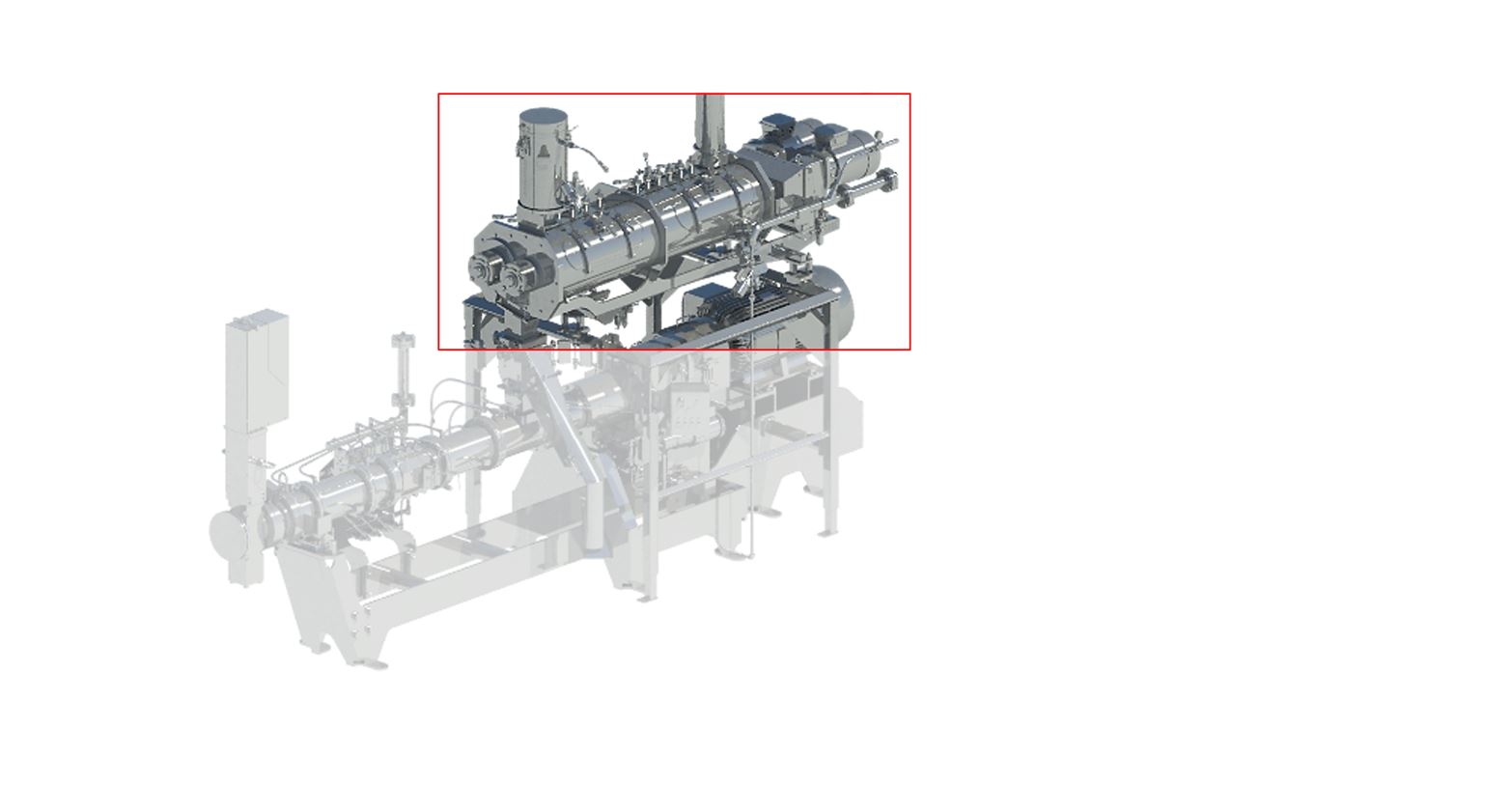

Maximize the efficiency of any Magnum ST extruder by using the Wenger High Intensity Preconditioner (HIP). A choice of three “mixing intensity” settings, controlled by process personnel, provides control of process requirements, allowing the increased addition of fiber, higher levels of whole grain additives and liquids in the recipe. The intense mixing provided by the High Intensity Preconditioner also creates smaller particles for more uniform hydration and better temperature control of the recipe.

-

Automatic Control Systems

As the ultimate in control systems, our automated process management (APM) utilizes our exclusive Human-Machine-Interface (HMI) to relieve the programmable logic controller of many time and memory tasks, including formula storage and manipulation, color graphic generation and trending.

-

Dry Ingredient Feed System

Choose from screw conveyors or vibratory feeders combined with bin capacities up to 4,250 liters. No matter the combination, the included Wenger bin feeder system ensures uninterrupted and rate-controllable metering of raw materials into the preconditioner and extruder. The system is further supported through load cells that weigh the dry mix in the bin and signal to the Loss-In-Weigh controller the flow rate through the feeder device.

-

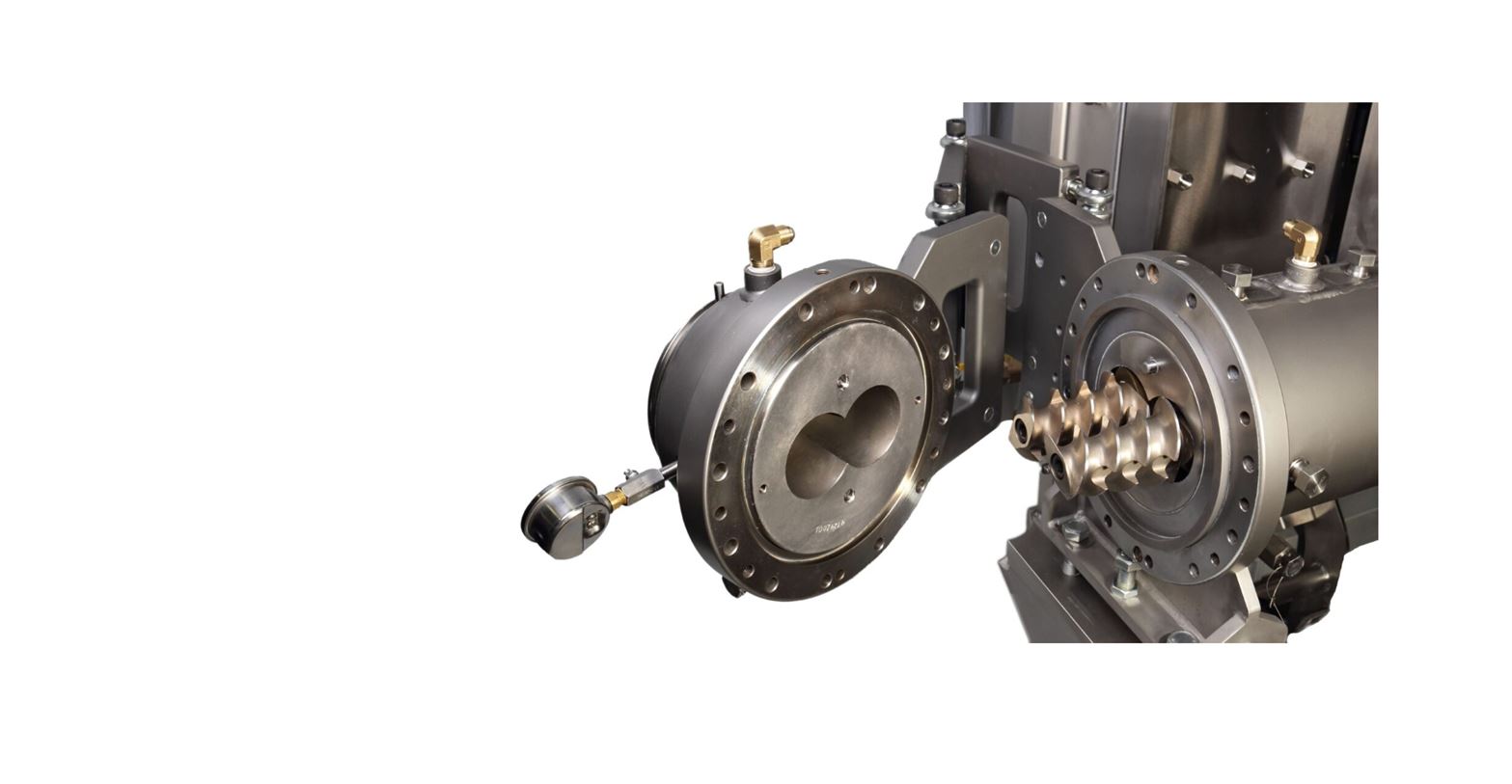

Convenient Barrel/Shaft Removal

Quick and simple barrel/shaft removal is facilitated through a hinged cone head that eliminates the need to open the barrel for cleaning or for changing final screw elements, simplifying maintenance for a higher degree of sanitation and allowing quicker service for less downtime.

-

Overhead Rail System

Unique to Wenger extruders, the overhead rail system permits operators to conveniently add process tools or remove extruder barrel components without heavy lifting or the need for additional equipment. The rail system also supports the hood, knife and additional options for cleaner floor space and greater durability.

Performance

| Model No. | Screw Diameter | Max Capacity (KG/HR) | Max Installed Power (kW) |

|---|---|---|---|

| TX-57 | 57 mm | 1000 | 60 |

| TX-85 | 85 mm | 2800 | 188 |

| TX-115 | 115 mm | 6800 | 450 |

| TX-138 | 138 mm | 9300 | 750 |

| TX-144 | 144 mm | 13000 | 900 |

| TX-168 | 168 mm | 16800 | 1000 |

Applications In

-

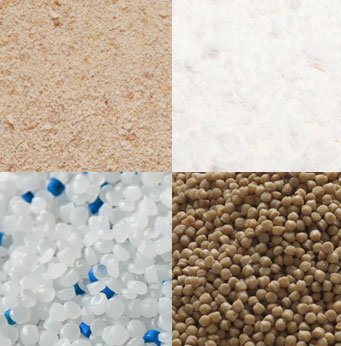

Food

Textured vegetable proteins, structured meat alternatives, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products, and many more

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

-

Industrial

With Wenger systems, you can create new products for industrial or consumer applications. Whatever idea you're thinking about, Wenger can help.

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project