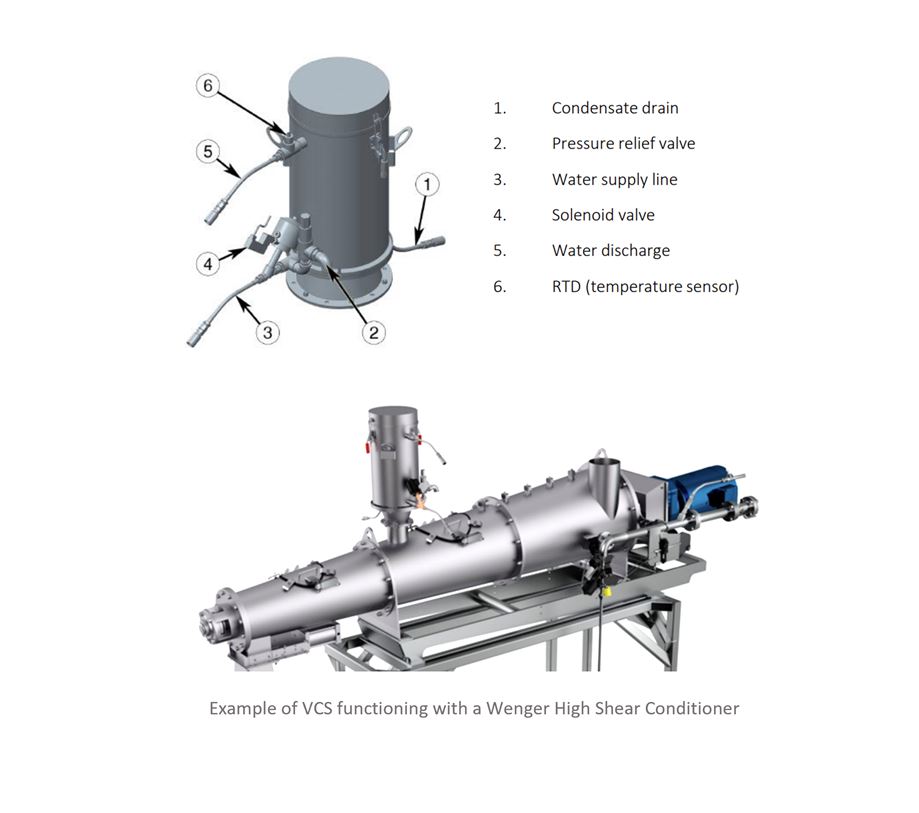

Vent Control System (VCS)

Improve Sanitation Around your Preconditioner

The patented Wenger Vent Control System (VCS) is a heat exchanger designed to fit onto existing preconditioners to ensure important sanitation and operating functions including:

- Reduced condensation above the preconditioner

- Elimination of pre-pasteurized fine particulates exhausting from preconditioner

- Reduced risk of microbial contamination in environment around preconditioner

- Reduced pressure in preconditioner that can create material buildup and poor flow

- Patent pending

How it Works

- VCS bolts directly to preconditioner

- Regular cold water supply is used to condense venting steam back into the process

- Water contact also captures fine particulate contained in the steam

- Warm water is discharged and can be piped to a reclaim system

- Water usage typically 1.0 gpm (4 litre/min) or less

- Inspection and cleaning is easy due to top access hatch

- Stainless steel construction

Applications In

-

Food

Textured vegetable proteins, structured meat alternatives, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products, and many more

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

-

Industrial

With Wenger systems, you can create new products for industrial or consumer applications. Whatever idea you're thinking about, Wenger can help.

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project