High Capacity Horizontal Dryers/Coolers

Wenger Dryers are Customized to Meet Process and Capacity Requirements

Airflow II - The industry standard for post-extrusion drying/cooling

- Wide variety of configurations, materials, and sizes

- Horizontal and vertical dryers

- 1-3 passes available

- Heat source can be gas, steam, or electric

- Adjustable air flows for optimal processing control and efficiency

- Sanitary configurations available

- Heated airflow from both sides of dryer

- Heavy duty construction

- Units are assembled and tested in our factory before shipped to ensure quality and performance

- Technical assistance available 24 hours a day

-

Process Air Flexibility

Dryers can be configured for optimum airflow. High process airflow velocity through the product bed increases drying energy efficiency while maximizing final product moisture uniformity.

Temperature profiling is optionally available in the TrueTemp configuration. This means each conveyor has separate temperature zones so the temperature can be matched to the product drying curve.

-

Process Control Options

Unique dryer control systems are designed for greater process efficiency. We offer full Automated Process Management systems linking the dryer to up or downstream components.

-

Multiple Product Spreader Options

Uniform drying is dependent on uniform bed loading. We offer several options for in-feed product spreaders:

- Sloped oscillating spout spreader — suitable for most applications

- Oscillating belt

- Finger

- Rake

- Vibratory

- Self adjusting leveling auger

-

Heat Source Options

Direct Heat

- Provided by natural gas, propane or butane

- Delivered to your work site with complete pre-plumbed, pre-wired gas train

- Equipped with safety interlocks meeting FM requirements

Indirect Heat

- Provided by heavy duty stainless steel coils protected by externally replaceable wire mesh screens

- Includes manifold, valves, traps and necessary plumbing components

-

Product Conveyor Options

Hinged or overlapping design with heavy duty tray is available in galvanized carbon steel or type 304 stainless steel construction. Tray perforations may be round holes or slots depending on the application. Woven screen continuous conveyors carried on heavy duty supports are optionally available for low or high temperature applications for small product sizes.

Applications In

-

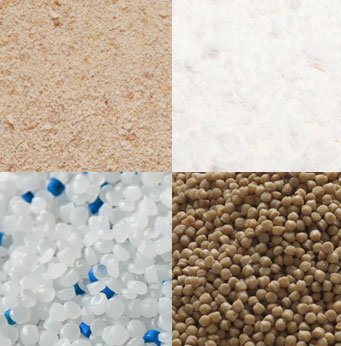

Food

Textured vegetable proteins, structured meat alternatives, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products, and many more

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

-

Industrial

With Wenger systems, you can create new products for industrial or consumer applications. Whatever idea you're thinking about, Wenger can help.

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project