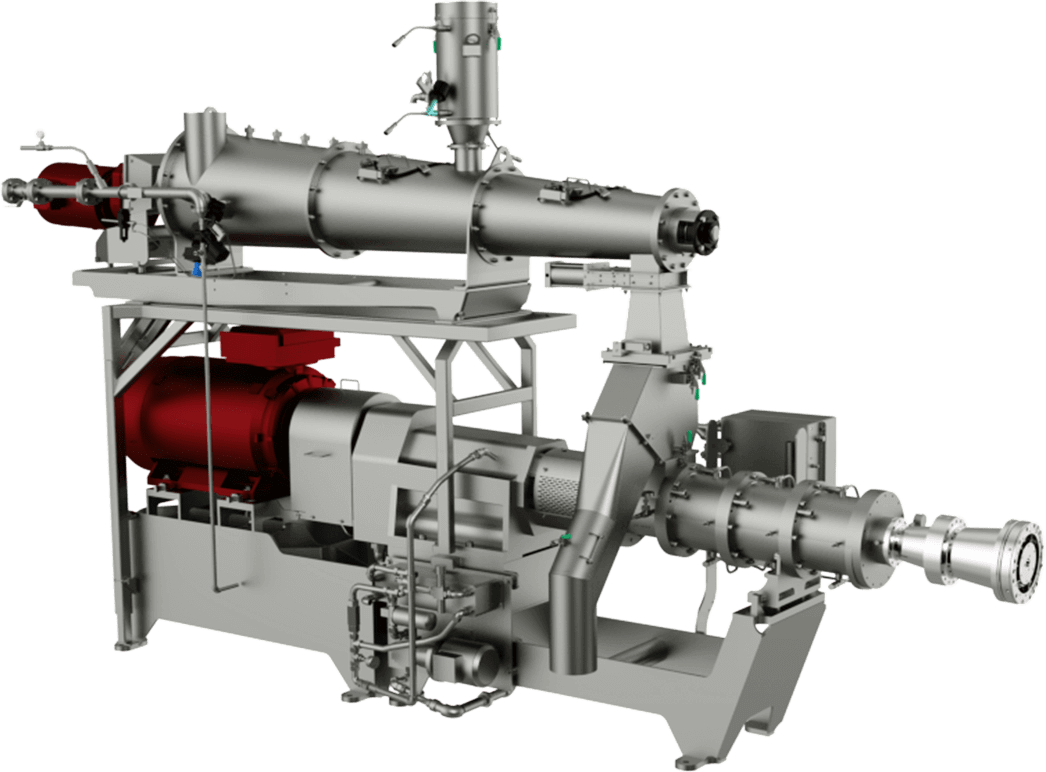

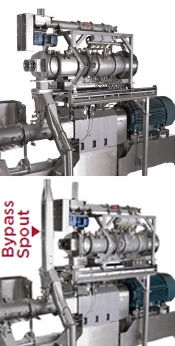

High SME Ratings & Unsurpassed Versatility

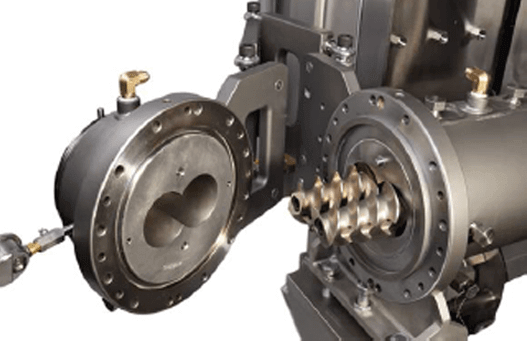

The Magnum ST Series redefines versatility for smaller extruders with no loss of capacity. The ability to use higher SME (Specific Mechanical Energy) settings to take extruded products to the next level.

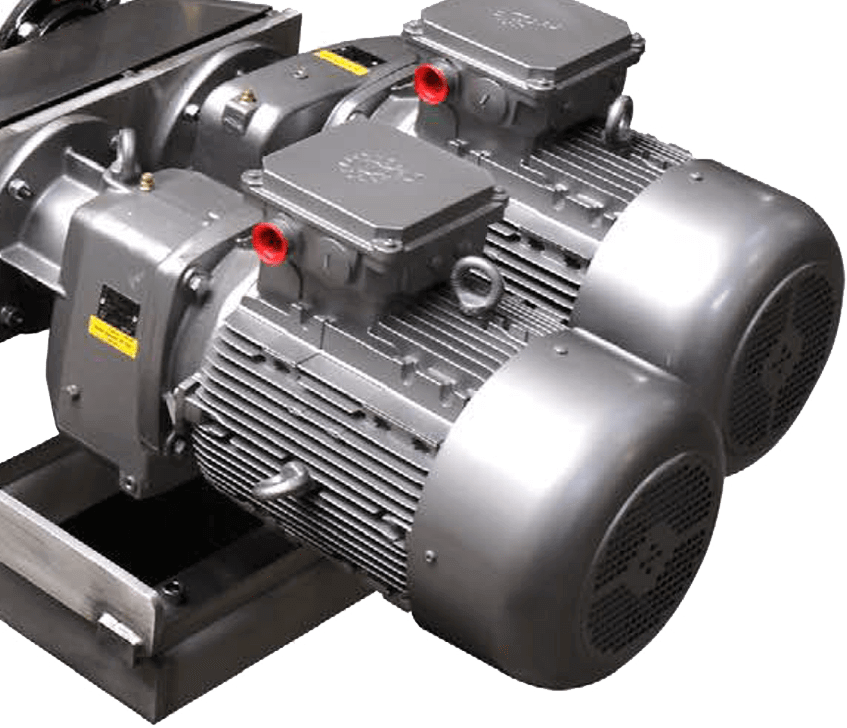

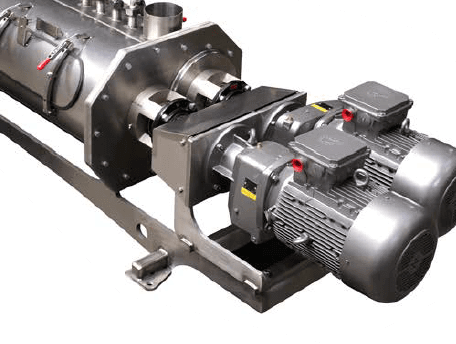

- Speed: Up to 1,200 rpm

- Power Levels: Up to 165 kWhr/t SME at volumetric capacity

Benefits of higher SME inputs

- Potential for lower bulk density

- Higher absorbency levels of liquid coating

- Smaller cell structure

- Enhancement of textural properties

- Higher cook levels