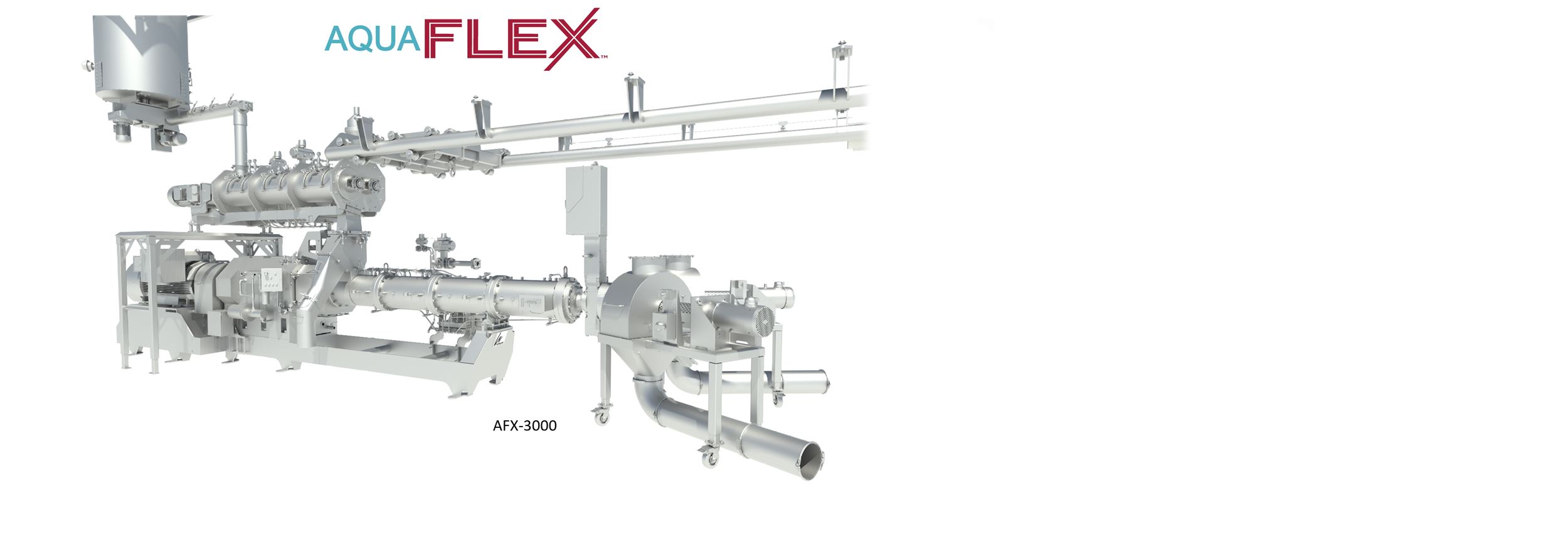

AquaFLEX™ Twin Screw Extruders

One of Wenger's innovative FLEX™ series extrusion systems

Produce high volumes of aquatic feed and animal food consistently in a wide range of pellet sizes and densities.

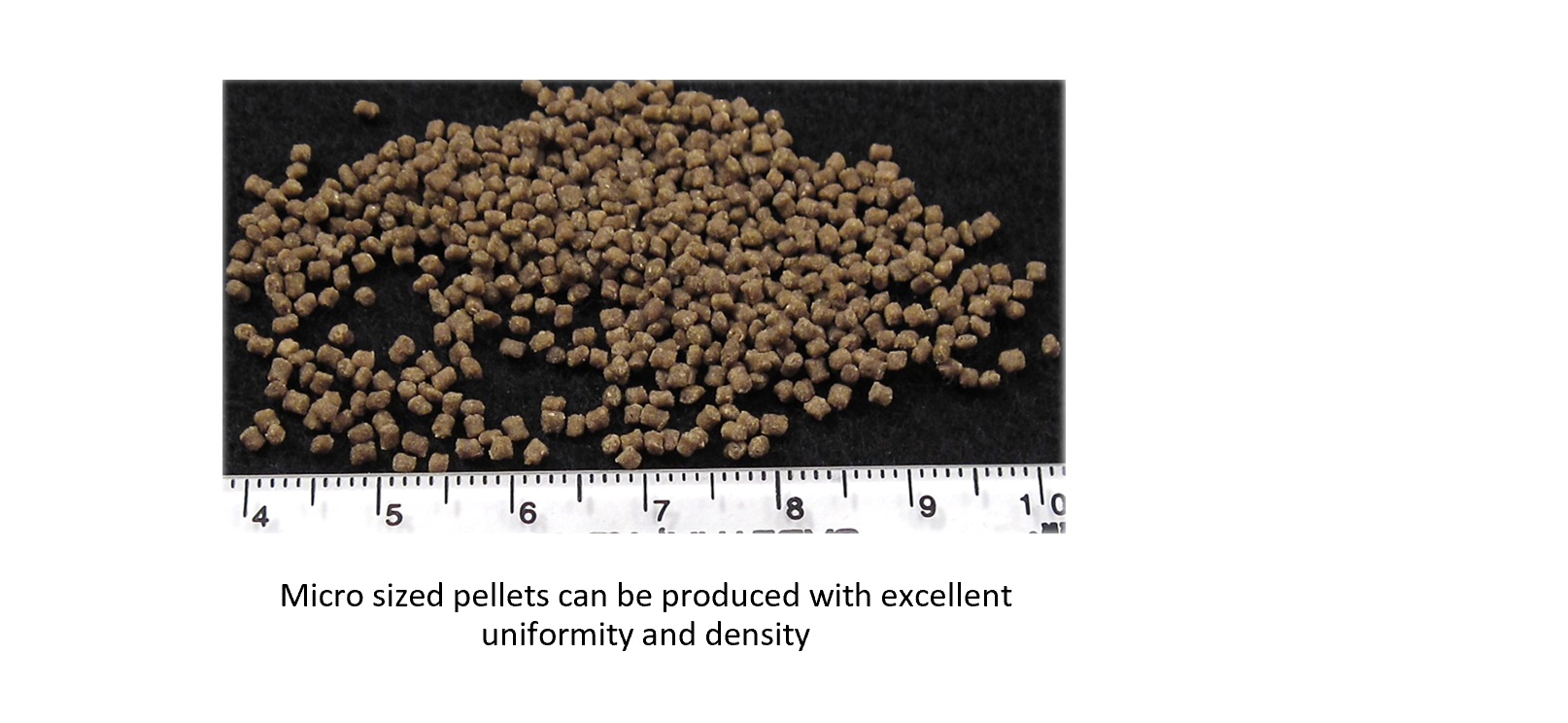

The AquaFLEX was engineered to overcome the historical challenges of processing high volumes of cooked extrudate into smaller sized pellets (<1mm) with sinking characteristics.

At high operating rates, extrudate will typically expand as it is pushed through the die, negatively impacting product density. This is most evident with small pellets. As a result, if traditional single screw extruders are used, production rates must be lowered to maintain proper density of small sized feeds.

Now you can have it all - with one extruder

The AquaFLEX is the industry's most flexible extrusion system for aquatic feed, enabling production of floating, slow sinking, and sinking products using a wide range of ingredients and recipies. Using twin screw technology, this innovative extruder excels at producing a highly uniform product with excellent nutrition retention and water stability.

Need to produce different pellet sizes for different species? No problem. The AquaFLEX can effectively produce floating and sinking feeds from 0.6mm to 10mm+.

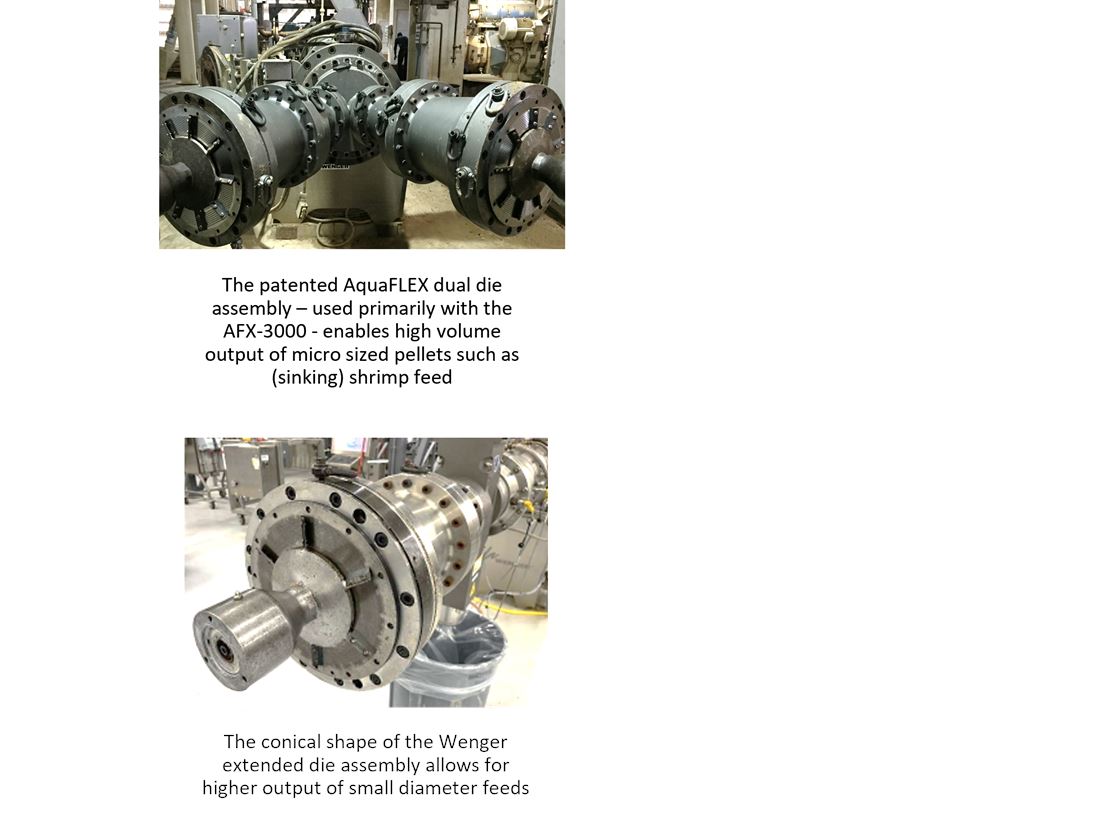

Need to produce different products at high volumes? No problem. The patented dual die assembly provides the flexilibty to produce sinking feeds (using both dies) as well as floating feeds (using just one die). Need a higher fiber product? Have a formula with higher levels of internal fat? Need a specific shape for portion control? All of these aspects - and more - can be achieved using one extrusion system: the AquaFLEX

To learn more about producing Micro Aquatic Feeds, read this Wenger article published in AquaFeed.com magazine:

As with all Wenger extruders, the AquaFLEX can be customized to fit each customer's unique requirements. To complete the feed production process, the AquaFLEX can be paired with a Wenger high volume horizontal dryer.

- Two available models: AFX-3000, AFX-600

- Maximum capacity of 13,000 kg/hr. (AFX-3000)

- Pellet sizes of 0.6mm to 10mm and larger

- Floating, slow sinking, and sinking products

- Maximum level of ingredient and formula flexbility

- Precise control of piece density and uniformity

- Excellent nutrient retention

- Water stability up to 7 hours (shrimp feed)

- Typically configured with Wenger's High Shear Conditioner or High Intensity Preconditioner, Shutdown Oil System and Overhead Rail System

- Ideal for high volume production of shrimp feed, but flexible enough to produce feed for salmon, trout, sea bass, cod, and yellow tail tuna

- Can also be used to produce high volumes of any type of feed. For pet food, this technology is available with the Wenger PetFLEX extrusion line.

Performance

| MAX CAPACITY (KG/HR) | MOTOR SIZE (HP) | MIN PELLET SIZE (MM) | |

|---|---|---|---|

| AFX-3000 | 9000-13000 | 300-600 | 0.6 |

| AFX-600 | 500-3000 | 150 | 0.6 |

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project