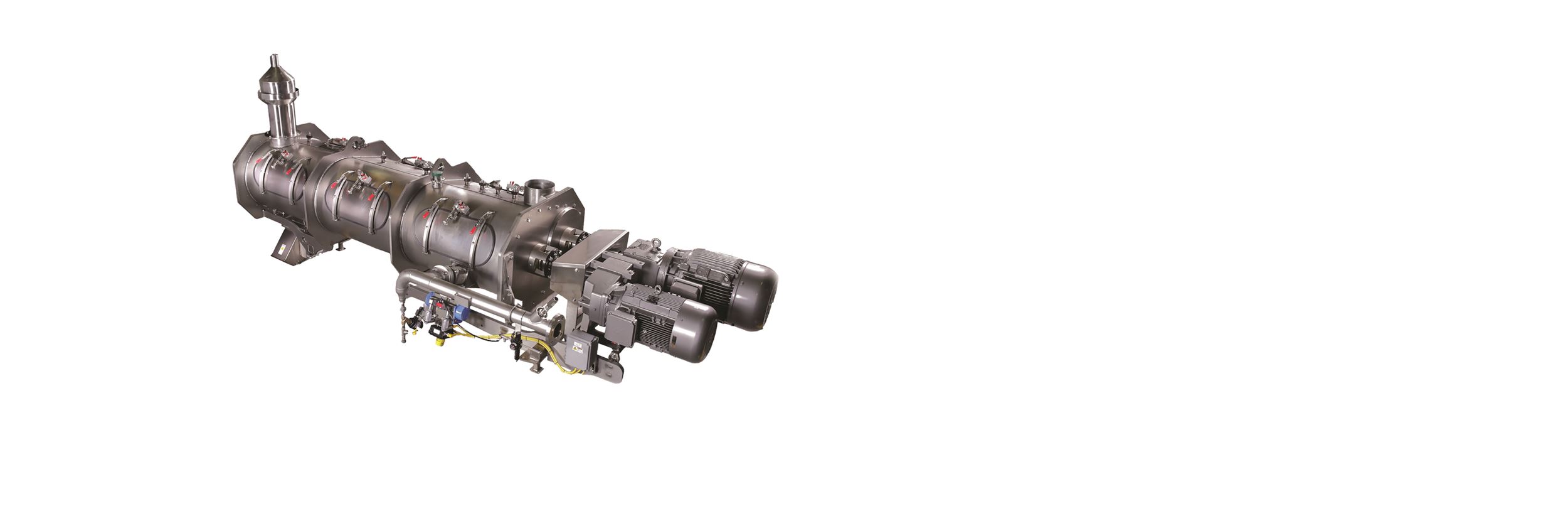

High Intensity Preconditioner (HIP)

Advanced Technology for the Best Mixing Process

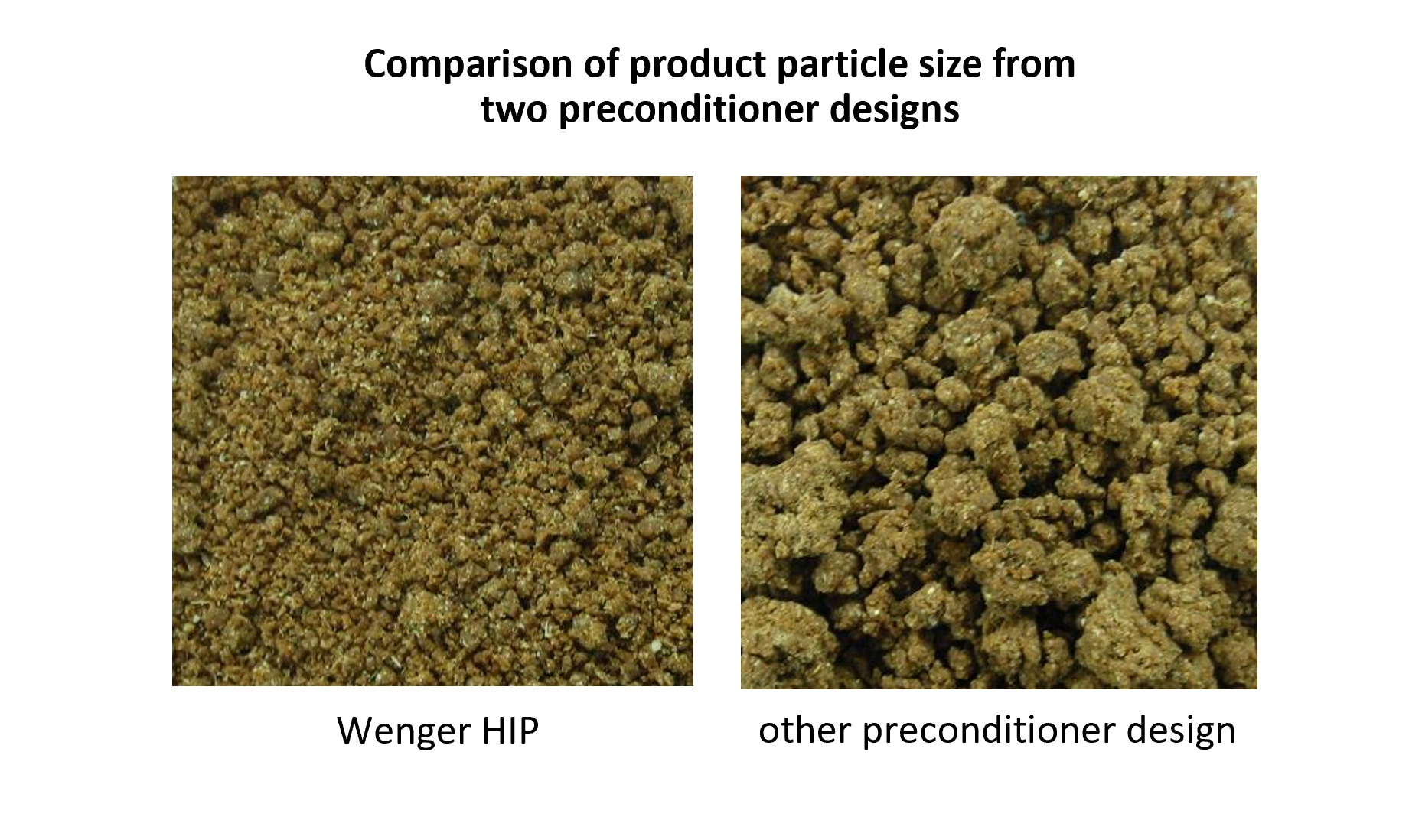

The Wenger High Intensity Preconditioner (HIP) provides an advanced level of mixing and control that makes it the perfect complement to Wenger extruders. Intensified mixing results in smaller particle sizes into the extruder, more uniform product moisture, and more consistent heating.

- Two independently driven shafts of different sizes

- Wide range of capacities and retention times

- Three mixing intensity settings

- Increases capacity through the extruder

- Improved pasteurization and sanitation

- Increased starch gelatinization

- Reduced product waste at startup/shut down

-

Allows increased addition of meat slurries and other liquids in the recipe

Any process that benefits from higher moistures and longer retention times will benefit from preconditioning

Engineered to Perform

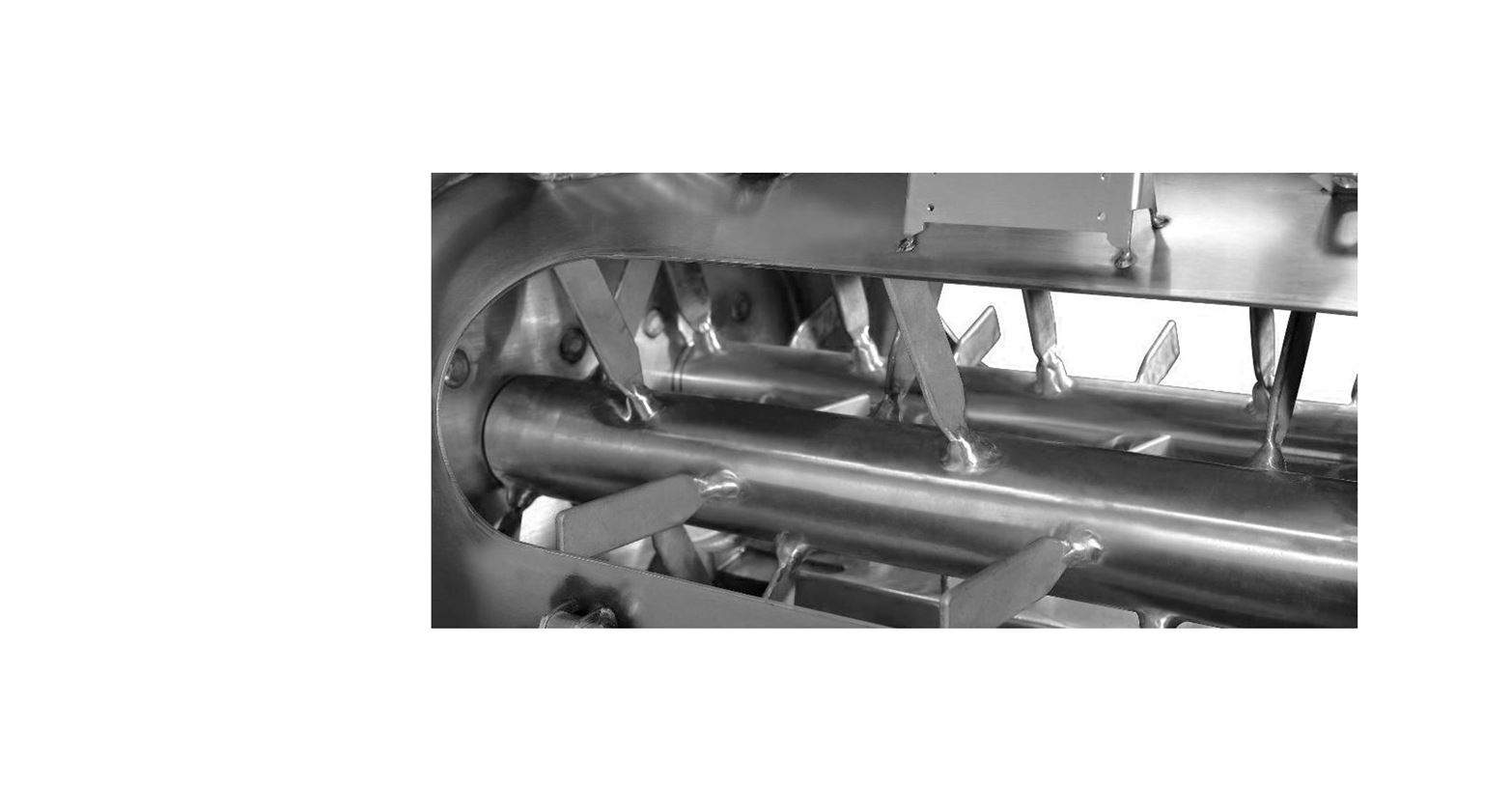

- Hygienic, dynamically balanced beaters designed for minimal buildup of material and easier cleaning

- Mixing capacities to 24,000 kg/hr

- Rotational speed controls

- Slide gate (used during cleaning) that also reduces discharge of under-processed material

- Highest levels of food hygiene and safety

- Coefficient of Variation = 2.65%

- Reduced mechanical energy input

- Increases thermal energy input

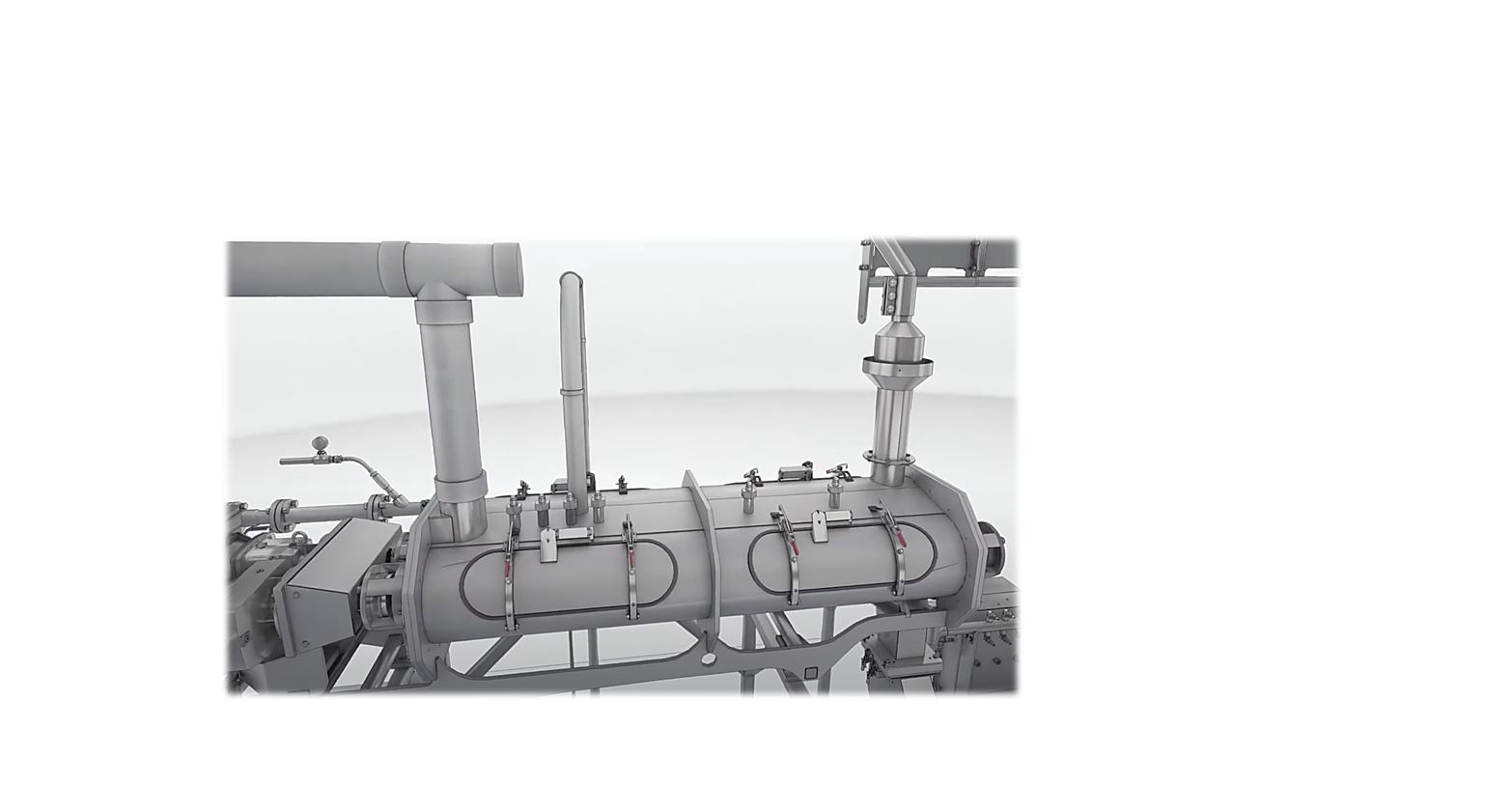

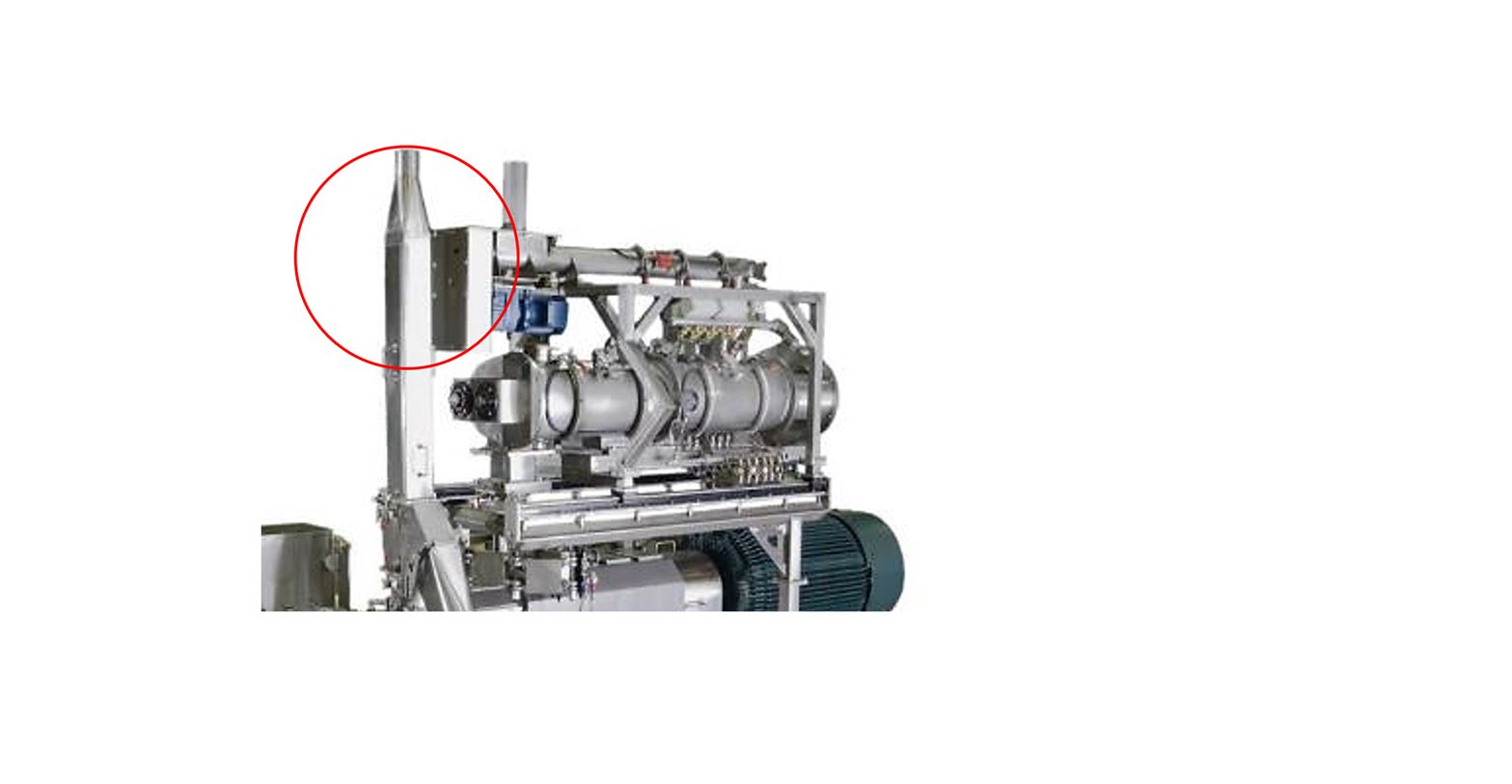

Roll Away Feature

Wenger's unique roll-away feature enables users to bypass the HIP in situations where preconditioning is not required, as dictated by recipe blends or final product characteristics.

A bypass spout (indicated by the red circle) can be moved into place easily as needed.

This feature provides excellent flexbility, enabling producers to create a wide range of products using one preconditioner/extruder configuration.

Applications In

-

Food

Textured vegetable proteins, structured meat alternatives, ingredients, protein crisps, breadings, RTE cereals, snacks, hybrid products, and many more

-

Pet Food

Traditional kibble, semi-moist, high fresh meat inclusion, treats (long, short, filled, dental) - and flexibility for new products with numerous ingredient options

-

Aquatic Feed

Floating, sinking, slow-sinking feeds, Recirculating Aquaculture System (RAS) feeds, and a wide variety of specialty feeds

-

Industrial

With Wenger systems, you can create new products for industrial or consumer applications. Whatever idea you're thinking about, Wenger can help.

Talk to a Product Specialist

to discuss the feasibility, design and implementation for your project